Saia-Burgess Controls AG

Manual for PCD2|3.W7x0

│ Document 26-

833 E

NG07 │ 2018-10-18

Configuration

3

3-4

Operation:

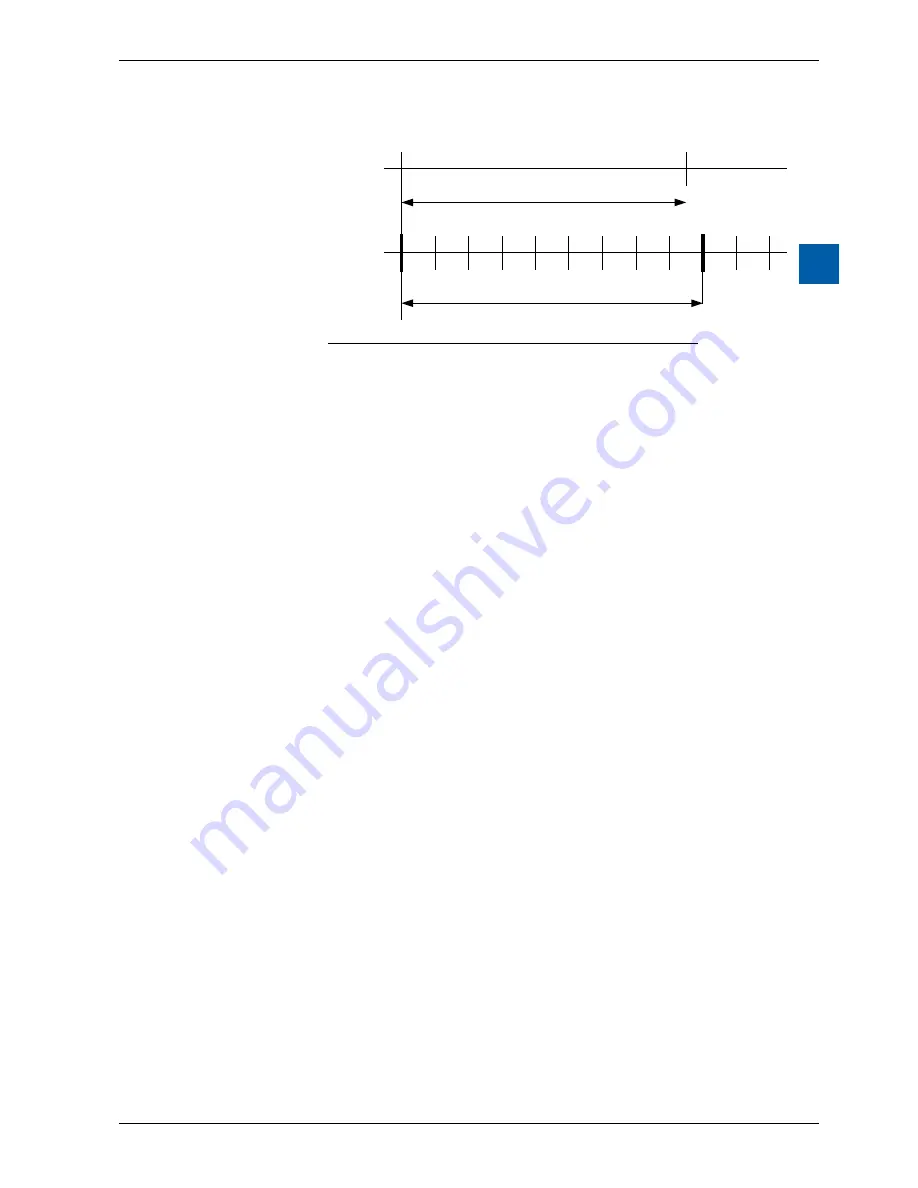

Acquisition cycles with

a small time constant

Time window

250 ms

T

(Time observed)

Change of weight in the time observed

T

Stability of the scale

Noise (WM_Status)

The instability of the weighing system can be read with a positive signal edge

at the

Noise

input to the FBox

WM_Status

. The instability is dependent on the

noise behaviour of the acquisition system, the vibration of the scale base and

the addition of the item to be weighed. In the next program cycle, a value for this

instability will appear at the

Noise

output. The range of values is from 0 to 255.

One unit represents 2

-18

of the nominal loading of the cell.

Reading the overload on the weighing cell

ReadO (WM_Config)

This input is used to read off the maximum overload ever reached on the

weighing cells. Most commercially available weighing cells are guaranteed to

withstand overloading up to 150% of their nominal load without damage. But it it

quite common, especially with small weighing cells, for them to be more heavily

overloaded.

The overload read off may range from 110% to 390%. The cell overload is

permanently stored in the weighing module and is overwritten each time a heavier

load is detected.

Clearing the overload memory

ClearO (WM_Config)

This input resets the permanent memory storing the overload value to 0. It is used

when initialising a new module, or in service where e.g. a defective weighing cell is

replaced.

Reading the status of the scale

Status (WM_Status)

The readout of the status of the scale is triggered by a positive signal edge at the

Status

input to the FBox

WM_Status

. When this FBox is activated, the data traf

-

fic between the weighing module and the Saia PCD

®

CPU is also checked. If this

data traffic is no longer assured, the

LifeFlag

on the

WM_Master

Box is set to “1”.

• 1 sec.

Differential weight =