Contents

1. Safety Instructions.................................................................................................................1-1

1-1. Safety Instructions for Service Engineers.......................................................................................................1-1

)HDWXUHVDQG6SHFL¿FDWLRQV

..................................................................................................2-1

2-1. Features .........................................................................................................................................................2-1

6SHFL¿FDWLRQV

.................................................................................................................................................2-3

&RPSDULQJ6SHFL¿FDWLRQVZLWK([LVWLQJ0RGHOV

.............................................................................................2-4

2SWLRQV6SHFL¿FDWLRQV

..................................................................................................................................2-6

3. Disassembly and Reassembly ..............................................................................................3-1

3-1. Tools for Disassembly and Reassembly.........................................................................................................3-1

3-2. Cautions for Disassembly and Reassembly ...................................................................................................3-2

3-3. Standard Disassembly Procedures ................................................................................................................3-4

3-4.

6SLQ1XW5HSDLULQJ%R[

.............................................................................................................................. 3-11

4. Troubleshooting.....................................................................................................................4-1

4-1. Error Modes....................................................................................................................................................4-1

4-2. Corrective Actions for Each Error Code..........................................................................................................4-6

([SORGHG9LHZVDQG3DUWV/LVW

..............................................................................................5-1

5-1. MAIN (BEST)..................................................................................................................................................5-2

$66<&29(5723%(67

...........................................................................................................................5-4

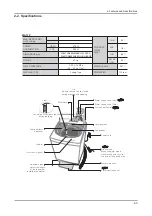

5-3. ASSY TUB&DRUM (BEST) ............................................................................................................................5-6

5-4. ASSY PAINT / ASSY BASE / ASSY CASE (BEST) ........................................................................................5-8

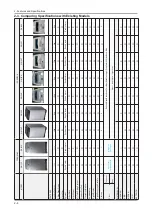

5-5. PARTS LIST (SCREW TYPE) (BEST)..........................................................................................................5-10

6. PCB Diagram.........................................................................................................................6-1

6-1. Main PCB / Sub PCB......................................................................................................................................6-1

6-2. Detailed Connector and Relay Terminal Block Manual (Main PCB)...............................................................6-3

7. Wiring Diagram......................................................................................................................7-1

7-1. Wiring Diagram...............................................................................................................................................7-1

8. Schematic Diagram ...............................................................................................................8-1

8-1. MAIN CONTROL ............................................................................................................................................8-1

8-2. SUB CONTROL..............................................................................................................................................8-2

Summary of Contents for WA10VP

Page 25: ...3 12 3 Disassembly and Reassembly Memo ...

Page 27: ...5 2 SORGHG 9LHZV DQG 3DUWV LVW 5 1 MAIN BEST P0001 U0084 F0062 ...

Page 31: ...5 6 5 3 ASSY TUB 262 9 4 ...

Page 38: ...6 4 6 PCB Diagram Memo ...

Page 40: ...7 2 UG Gk Mome ...

Page 41: ...8 1 _UGz Gk 1 Vfkhpdwlf Gldjudp 041 PDLQ FRQWURO G Gk G G G G G Gz G U ...

Page 42: ...8 2 _UGz Gk 051 VXE FRQWURO G Gk G G G G G Gz G U ...