www.larius.com

9

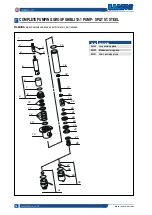

GHIBLI 10:1

ED.

05 - 10/2020 - Cod. 150154

Always close the compressed air supply and release the pressure in the plant before performing any check or

replacement of parts of the pump.

TROUBLESHOOTING

Problem

Possible cause

Solution

The pump does not start

Feed air not sufficient

Check on the air supply line. Increase

the diameter of the feed hose.

Outlet product line clogged

Clean. Disconnect the outlet hose of the

product. Feed the pump at he minimum

pressure and verify if the pump starts

without the outlet hose.

Inlet product line clogged

Clean the suction pipe.

Pneumatic motor blocked at the upper or

lower stroke end (Dead Center)

Reduce feed pressure;

Manually reset the pneumatic motor

(see on page 10);

Crosspiece screws failure of the pneu-

matic motor

Replace the screws (see on page 10).

Accelerated working and no pressure

of the pump

Lack of product

Add product.

The pumps sucks air

Check the flexible suction hose (only for

suction threaded valve version).

The product is too fluid

Adjust the suction valve (see on page 11).

Gaskets of the pumping rod worn

Replace the lower gaskets (see on

page 12).

The ball of the suction valve does not

perfectly "close"

Disassemble the suction valve and clean

(see on page 11).

The pump works but the flow of

product is not sufficient

Air feed pressure is too low

Increase air pressure.

Gaskets of the pumping rod worn

Replace the lower gaskets (see on

page 12).

Inlet product line clogged

Clean the suction pipe.

Product is too thick

Adjust the suction valve (see on page 11).

The ball of the suction valve does not

perfectly "close"

Disassemble the suction valve and clean

(see on page 11).

L