www.larius.com

7

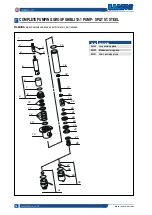

GHIBLI 10:1

ED.

05 - 10/2020 - Cod. 150154

Pos.

Code

Description

1

510600

Trolley mounted pneumatic ram - single column

510090

Pneumatic ram 30 lt. - double column

2

510781

Shovel plate for 30 lt. drums

Pos.

Code

Description

1

96038

Wall support

2

16608

Flexible suction hose with stainless dip tube

16612

Flexible suction hose with stainless steel dip tube

GHIBLI 10 :1

pump short version, with suction threaded valve

fixed on wall support and with flexible suction hose.

SETTING-UP

CONNECTION TO THE FEED AIR

For pump feed use a tube with an internal diameter no lower

than 10 mm.

CONNECTION OF THE FLUID OUTLET HOSE

Connect the high pressure hose to the outlet of the pump.

It is recommended to tighten the fittings.

WASHING OF THE BRAND NEW EQUIPMENT

The pump has been tested at our factory with light mineral oil,

left inside the pumping element as protection. Before sucking

the fluid, wash with diluent. To wash the equipment follow the

procedure "

Cleaning at the end of the work

" described on page 7.

OPERATION

CLEANING AT END OF WORK

• Dip the fluid pumping hose into the product tank

(for the

suction threaded valve version, dip the flexible suction hose)

.

• Make the compressed air flow into the pump. It is advisable

to adjust air pressure to minimum value necessary for its

continuous working.

• When the product chamber is full, pump will start working

and then stop. Pump will start working again every time the

trigger of the spray gun is pressed or the delivery valve is

opened.

• Check that the packing nut is not loosened causing the co-

ming out of the product. To tighten the packing nut follow the

instructions indicated in the section "

Routine maintenance

"

on page 8.

• Stop the air supply to the pump.

• Lift the pump and dip the pumping hose into the tank con-

taining washing solvent or a washing liquid specific for the

products to be used with the pump (

for suction threaded

valve version, lift the flexible hose

).

• Make compressed air flow into the pump. It is advisable to

adjust the air pressure to minimum value necessary to its

continuous working.

• Point the spray gun or the delivery valve at a collecting tank

and drain all the product left inside the pump till a clean

washing product comes out.

• Now stop the air supply to the pump and release the residual

pressure.

• In case of long activity, the operations of sucking and leaving

light mineral oil inside the pumping element are suggested.

1

2

H

Install at the inlet of the pump an air pressure

regulator

(it is suggested complete with

condensate filter and lubricator)

. The outlet

pressure of the material is 10 times the inlet

pressure of the pump feed air. Therefore, it is

extremely important to adjust the value of the

feed air pressure.

I

Check all the fittings for connection of the different

components

(pump, flexible hose, spray gun, etc.)

before using the equipment.

J

Store possible dangerous fluids in proper

containers. Their disposal must be performed in

accordance with the regulations in force about

the industrial waste goods.