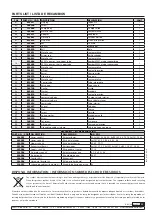

4

853 831 R. 02/20

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2020_02_05-09:30

EN

DESCRIPTION

Compressed air operated piston-type reciprocating pump. This ultra high pressure pump is compatible with mineral and synthetic grease and

suitable for applications where extreme grease pressure is needed.

WARNINGS - ULTRA HIGH PRESSURE EQUIPMENT!

WARNING!

Carefully read all instruction manuals, tags, and

labels before operating the equipment. This equipment is for

professional use only.

WARNING!

ATEX installation: be sure to connect the grounding

cable correctly (fig 1 and 2).

• The use of non compatible fluids may cause damage in the pump and

serious personal injury. This equipment is not intended for use with

fluids that fall within the Group 1 fluid as defined that are explosive,

extremely flammable, highly flammable, flammable, very toxic, toxic,

oxidizing or where the vapor pressure if greater than 0,5 bar (7 psi)

above the pressure atmospheric at the maximum allowable

temperature.

• The pump generates ULTRA HIGH PRESSURE. WARNING! Do not exceed

the maximum air inlet pressure of 7 bar (100 psi). It is STRONGLY

RECOMMENDED to use a pressure relief valve in the air input of the

pump, set to 7 bar (100 psi) max, to avoid overpressure in the pump.

!

!

• A direct hit against the human body may result in an injury.

• The use of some kind of lifter is strongly recommended for manipulating

or servicing tasks, since the pump weighs aprox. 59 kg (130 lb).

• This unit may have STORED PRESSURE, release all pressure and disconnect

from any fluid systems before servicing. To ensure safe operation of this

unit, all service work should be by qualified personnel only.

• When not in use, be sure to shut off the air supply to avoid accidents.

• Do not alter or modify this equipment. Use only Samoa Industrial, S.A.

genuine components. Any unauthorized tampering with this

equipment, improper use, poor maintenance or removal of

identification labels may invalidate the guarantee.

• All fittings in the system connected to the outlet of the pump should

be suitable for the maximum possible pressure generated by the

pump/air motor. If the systems cannot be designed to take the

maximum pressure produced by the pump, safety valves or diverter

valves should be fitted.

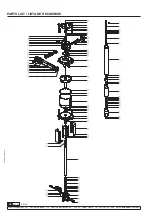

INSTALLATION

When mounted directly on a drum, It is recommended to use a sturdy

cover due to weight considerations.

Example:

mounting with cover (418026/418018) for 185/50 kg

(400/120 lb) drum. Insert the pump through the cover and fasten it with

the enclosed screws. Insert the pump into the drum and fasten the cover

onto the drum firmly (see figure 1). For heavy greases, the use of a

follower plate is recommended (417015/417016).

It is also possible to install the pump in tanks/containers equipped with

a 3” female camlock connection, using our 3” camlock adapter kit

(534900), usually in horizontal/inclined position.

Pump can be placed on a flat surface with the available stand 534906.

Fig. 1

The pump can be mounted directly on 50 kg (120 lb) and 185 kg (400 lb) drums. However, it is strongly recommended the use of a lifter/RAM and

a coupled plate.

418026/418018

WARNING! THIS EQUIPMENT IS DESIGNED FOR PUMPING GREASE. DO NOT PUMP ANY OTHER FLUID.

!

Securely attach the clamp of

supplied cable to a ground

element of the installation

Ensure the grounding

cable is securely fastened

to the pump body

ATEX: securely fasten the supplied grounding cable to

the body of the pump, and firmly attach the clamp to

a grounded element of the installation

female camlock

from bulk tank

534907

534900

534900

Fig. 2