5

R. 02/20 853 831

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2020_02_05-09:30

EN

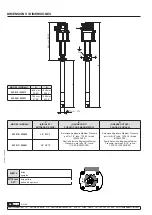

GAUGE PORT:

Autoclave Engineers Medium Pressure port for 1/4”

tube, 7/16-20 thread (SF250CX20).

AIR CONNECTION:

compressed air supply must be set between 2 and

7 bar (30 and 100 psi). The recommended pressure is the lowest one

that fits the flowrate requirements,

being 7 bar (100 psi) the limit

air pressure which should never be overpassed

. An air closing

valve must be installed, in order to be able to close the compressed air

line at the end of the day.

CONNECTIONS

This pump is self–priming. To prime it the first time, it is convenient to

connect the air supply to the pump while keeping the outlet valve

opened, and increase the air pressure slowly from 0 to the desired

pressure by using a pressure regulator.

Once grease starts flowing through all the outlets, the pump is primed.

The pump starts to pump when an outlet valve is opened.

OPERATION

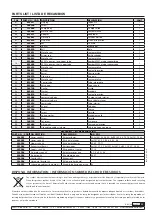

Symptoms

Possible Reasons

Solutions

The pump is not working or there is

no grease delivery.

No suitable air supply pressure.

Increase the air supply pressure.

Some outlet circuit element is clogged or closed.

Clean or open the outlet circuit.

There is an air pocket in the grease inlet area.

Stir and repack the grease.

The pump begins to operate very fast.

The drum is empty or the grease level is beneath the

suction tube inlet.

Replace the drum or insert the suction tube until

the inlet reaches the grease level.

The pump keeps on operating

although the grease outlet is closed.

There is a grease leakage at some point in the circuit.

Verify and tighten or repair.

Contamination in the upper valve.

Disassemble and clean. Replace if damaged.

Contamination in the foot valve.

Disassemble and clean. Replace if damaged.

Grease leakage through the warning

hole on pump body (63)

Scratched piston rod (51) or worn or damaged seals

(54, 56, 59).

Verify the piston rod (51) and replace damaged

/ worn parts.

Air leakage through the air outlet

muffler (22).

Damaged or worn piston O ring (36).

Replace O Ring (36).

The air seals (6, 10) of the inverter assembly are

damaged or worn.

Replace the air seal (6, 10).

Damaged or worn spool (18) seals.

Replace the spool (18).

Grease output too low or diminishes

over time.

Contamination in the foot valve.

Remove and clean. Replace if damaged.

Contamination in the upper valve.

Remove and clean. Replace if damaged.

The exhaust muffler is clogged by compressed air dirt

or lubricant.

Replace the muffler felt (25, 27).

TROUBLESHOOTING

WARNING!

In ATEX installations, ensure

the grounding cable is properly attached

to the pump and to the installation ground.

AIR INLET

3/4” NPT

WARNING!

CONNECT ONLY ULTRA HIGH PRESSURE

ACCESSORIES WITH MINIMUM PRESSURE RATING OF

1400 bar (20.000 psi).

MATERIAL OUTLET:

Autoclave Engineers Medium Pressure port for 9/16”

tube, 13/16-16 thread (SF562CX20)

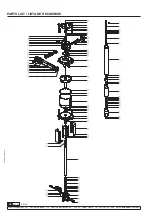

Fig. 3

GREASE CONNECTIONS:

only ultra high pressure fittings/accessories/

tubing must be used. The pump is able to deliver grease up to

1400 bar (20.000 psi) when fed at 7 bar (100 psi) of air pressure.

Installation components must be rated to withstand that pressure. A

gauge port is provided, being factory closed with a proper plug.

NOTE: It is important that the foot valve do not come in contact with dirty

areas, such as a workshop floor, because it may become contaminated with

dirt or other particles that can damage the seals.

!

!