SAFIRE 2400Di, 2600Di, 3200Di and 3600Di Diesel / fuel oil heaters

5

USAGE, INSTALLATION AND MAINTENANCE

January 2011

SF- Lämmitin Oy

Tilhenkatu 1 20610 Turku Finland Puh/Fax +358(0)2-2443282

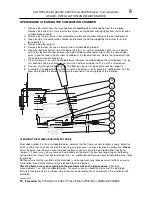

INDICATOR LEDS

Indicator LEDs on the control panel:

Green LED

above the switch of the basic control

panel: the heater is on. If the LED is not on when

starting the heater, the heater’s power supply is

probably disconnected.

Green LED (flame)

on the control

panel: the flame sensor has detected

a flame and combustion is in process.

Indicator LEDs on the end of the heater:

Green LED D10

: the flame sensor

has detected a flame and

combustion is in process.

Yellow LED D2

: the voltage is low, under

10,8V (or under 9V during the ignition).

The battery voltage may be too low, the power supply

cables too thin or some connection in the wiring loose.

During the start the voltage can be lower, because the

voltage drop caused by the filament current in the power

supply cables can be up to 0,5V. If the voltage drops

below the limits mentioned above, the aftercooling

mode activates and the heater turns off.

Red LED D9

: malfunction detected, the

combustion stops.

On the end of the heater is a display which indicates the

type of malfunction (see Malfunctions; NB: the display is

upside down). If you have turned the heater off, you can

see the latest malfunction type on the display again by

turning the switch to “VENT”: the latest error code

shows on the display.

GENIUS CONTROL PANEL

Control the heater according to the instructions

indicated on the GENIUS control panel. The normal

start: Push BACK, the text HEATER CONTROL

appears on the display; push OK, the text START

appears on the display, push OK and the heater starts.

The menu ADJUST POWER allows you to adjust either

the power or the temperature. Choose menu items with

arrow keys, accept with OK.

If you desire extra strong ventilation, choose DRYING

VENTILATE. On this mode the heater takes more fresh

air; this improves the drying effect while the heating

power is low (practical f. ex. in the summer when the air

is damp but not very cold).

Return to the main menu with BACK. NB! All selections

are not allowed in every mode.

STARTING THE HEATER

Start the heater with

ON/HEAT-OFF-VENT

-switch.

Green LED above the switch

turns on. The pump

operates (you can hear tapping, the dot on the circuit

board display blinks), the fans are operating.

Green LED (flame)

on the end of the

heater and on the basic control panel

lights about 1 1/2–3 minutes after the

start when the flame sensor has detected

a sufficient flame.

The ignition process ends in about 6 1/2 minutes. The

heater operates on the power set with the thermostat or

with the adjustment knob; the main fan measures the

temperature of the room and operates on sufficient

power.

HEATING POWER

Make sure that the temperature chosen on the

thermostat or the chosen power settings correspond to

your needs.

ADJUSTING THE HEATING POWER

If your heater has a thermostat, it will adjust the power

automatically. If you want to change the heating power

temporarily, adjust the temperature settings; the power

level will change to correspond to the set limit.

If your heater doesn’t have a thermostat, adjust the

power manually with the adjustment knob. NB! The

main fan doesn’t operate on the new power level until

the temperature of the air requires it.

TURNING OFF THE HEATER

Turn the heater off by turning the switch into OFF

position; the pump stops, the heater goes into

aftercooling mode and after that turns off.

Do not cut the power supply off f. ex. from the main

switch when the aftercooling is on process (about 6

1/2 minutes)!

If the power supply is cut off, the heater starts next time

only after it is set on ventilating mode

(error code A).

+ -