17

Model ASx-900|

Owner’s Manual

| Version no: 1

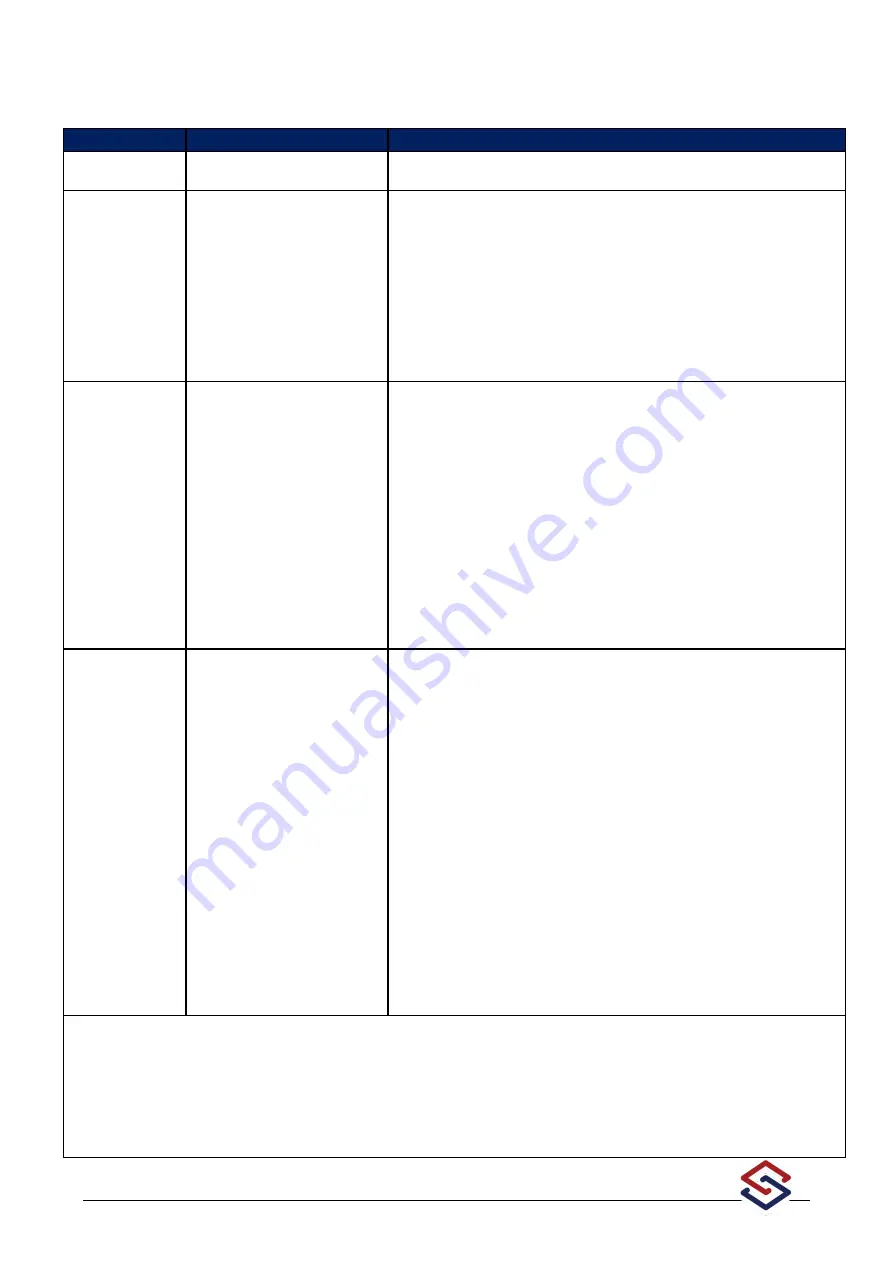

Problem

Possible Causes

Remedy

4) Flow controller may be

fully closed.

Open flow controller as described in section 4.11.

5) Thermal overload on

motor contactor may

have tripped. (Three

phase lift table only)

This condition will

invariably have

occurred during raise

and will also have

disabled the raise

function.

Reset the overload by opening the contactor box and

pressing the red reset button on the overload. Investigate

and rectify the source of the overload before lowering the lift

table in case access beneath the platform is required.

6) Down solenoid fuse on

the control board may

have blown

Check the down solenoid fuse mounted on the control board.

Open the enclosure housing the control board and check the

fuse with a multi-meter. The fuse is 1 amp 1" long x 1/4"

diam ceramic type. When replacing the board, carefully

bunch cores beneath the board. Ensure that board stand-

offs sit in the bottom of the box without fouling cables.

SmartLift diagnosis as follows:

(1) Check that the orange "Power on" LED is on and that the

red "Safety bar tripped" is off.

(2) Press the down control. If the green "Down control

made" is on and the orange "Power to down solenoid" is not,

the down solenoid fuse on the board is blown.

Lift table will

not lower.

Cont.

7) If none of the above, a

mechanical, electrical

or hydraulic fault may

exist.

Contact your Safetech agent.

SmartLift diagnosis:

(1) Fault in controller

i. Check that the orange "Power on" LED is on.

ii. Press the down control. The green "Down control made"

LED should illuminate, regardless of the status of the safety

bar. If not, there is an electrical fault in the controller.

(2) Burnt out solenoid

i. Check that the orange "Power on" LED is on.

ii. Remove the solenoid from the valve spindle and insert a

screwdriver through the bore as described below.

iii. Press the down control. If the green "Down control made"

and the orange "Power to down solenoid" illuminate but

magnetic pull cannot be felt on the screwdriver, the solenoid

is burnt out.

With causes 1,3, 5, & 6 the solenoid will not be energised when the down control is pressed.

With causes 2 & 4, the solenoid will be energised.

The energising of the solenoid can be verified be removing the solenoid from the down valve spindle,

inserting a screwdriver through the solenoid bore and pressing the down control. If the solenoid

energises, the magnetic pull can be clearly felt on the screwdriver. This is a useful test to help isolate

problems.