21

XL-FW535 Rev G · 2014-08-11 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and

logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

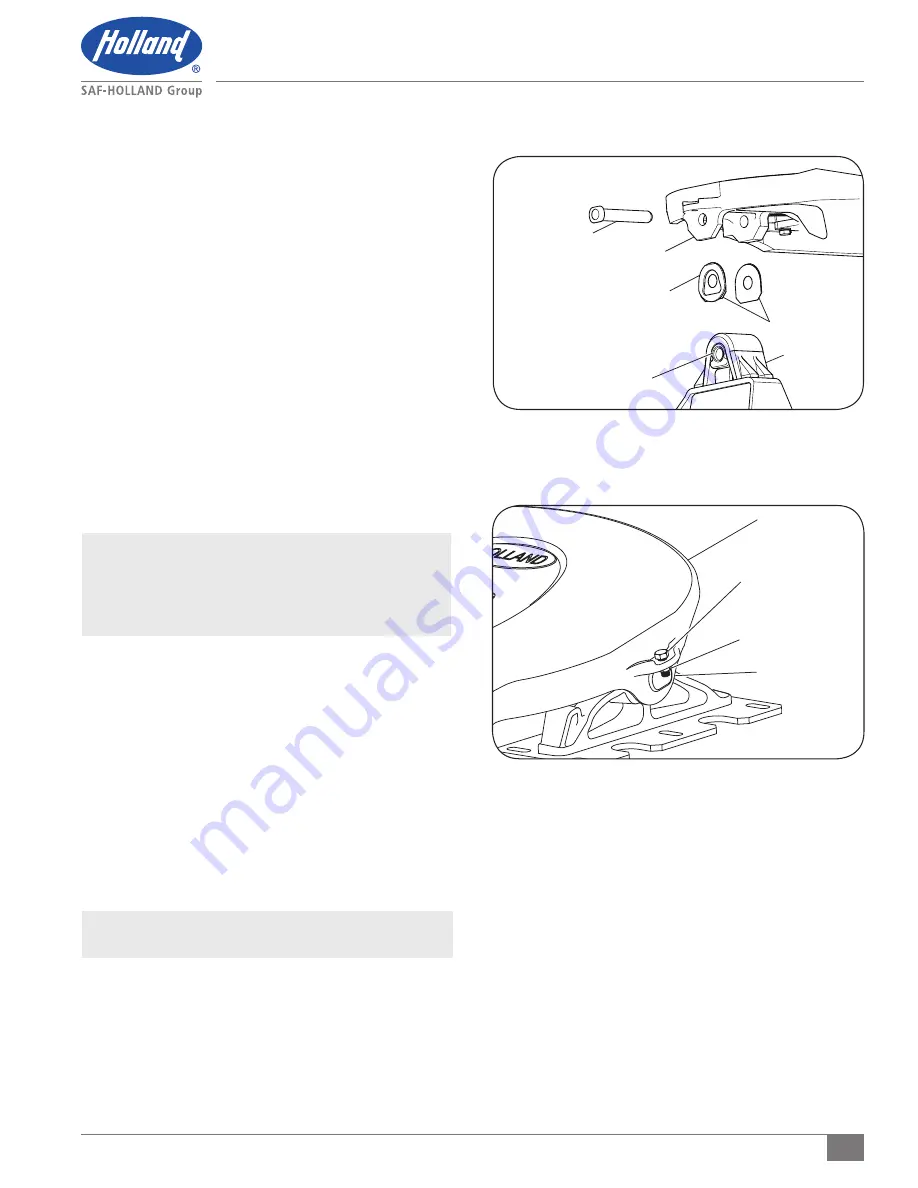

Figure 31

Figure 32

Top Plate Installation

3. Line up the holes of a new metal bracket shim and

rubber washer between the outside ear of the fifth

wheel and the mounting bracket. Rubber washer must

be placed between the outside ear and the metal

bracket shim

(Figure 31)

.

4. Insert the bracket pin through the outside ear of the

fifth wheel, metal bracket shim, rubber washer, and

halfway through the mounting bracket to hold the

bracket shims in place

(Figure 31)

.

5. Repeat Steps 3-4 for the opposite side of the fifth

wheel. If needed, the fifth wheel could be pushed

from side-to-side on the brackets to create space for

the bracket shims.

6. Once the outside bracket shims are installed, line up

the holes of a new metal bracket shim between the

inside ear of the fifth wheel and the mounting bracket.

7. Complete insertion of the bracket pin through the

bracket shim and into the inside of the fifth wheel.

8. Repeat Steps 6-7 for the last remaining metal bracket

shim between the other inside ear and mounting bracket.

IMPORTANT: I

f there is NOT enough room for the rubber

washers to be installed, or when installed

the fifth wheel DOES NOT freely articulate,

remove rubber washers and install metal

bracket shims only.

9. Secure bracket pins by installing the 1/2"-20 x 1-1/4"

hex head cap screws and 1/2"-20 lock nuts

(Figure 32)

. Torque the hex head cap screws to

50-60 ft.-lbs. (68-81 N•m).

12. Top Plate Installation

(for cast mounting brackets)

1. If pocket inserts are dislodged from fifth wheel top plate,

clean pocket area of forging and apply a strip of double-

face tape in the bottom of pockets. Install pocket inserts

by pressing down into pockets

(Figure 30).

2. Using a lifting device capable of lifting 500 lbs. (227 kg),

install the fifth wheel top plate onto its mounting base.

NOTE:

Follow instructions published by lifting device

manufacturer for proper operation of lifting device.

3. Install the bracket pins through fifth wheel top plate and

mounting base and secure by installing the 1/2"-20 x 1-1/4"

hex head cap screws and 1/2"-20 lock nuts

(Figure 32)

.

Torque the hex head cap screws to 50-60 ft.-lbs. (68-81 N

•

m).

BRACKET PIN

OUTSIDE EAR

RUBBER WASHER

BRACKET SHIMS

RUBBER CUSHION

MOUNTING

BRACKET

TOP PLATE

1/2"-20 LOCK NUT

BRACKET PIN

1/2"-20 x 1-1/4"

HEX HEAD

CAP SCREW