6 - 5

176.12

.A03

Revision 01 Date 14.11.2001

OPERATING INSTRUCTIONS

6

6.2

WORK CYCLE

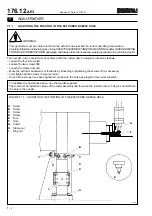

FIGURE 6.2 - WORK CYCLE

1

The caps are fed continuously (facing the right way up and in lines) to the insertion drum.

2

Insertion drum: sprue cut (if present in the cap); pellet placed in caps

3

Plastic compound feed hopper

4

Plastic compound extruder

5

First transfer unit

6

Forming unit: the liners are formed inside the caps

7

Second transfer unit and cap cooling

8

Quality control unit: caps checked with a pneumatic/mechanical system

9

Discharge unit

10 Exit channel and cap counter

1st Rej. Caps rejected because defects detected by vision system (if installed).

2nd Rej. Caps rejected because of defects detected by pneumo-mechanical system and sensor that detects

double liners

2

5

3

4

6

7

8

9

10

2

°

Sc.

1

°

Sc.

1

T0601

1st Rej.

2nd Rej.

Summary of Contents for PMV 224

Page 2: ...TABLE OF CONTENTS 176 12 A03 0 2 Revision 01 Date 14 11 2001 ...

Page 4: ...TABLE OF CONTENTS 176 12 A03 0 4 Revision 01 Date 14 11 2001 ...

Page 34: ...2 22 176 12 A03 Revision 01 Date 14 11 2001 2 MAIN FEATURES ...

Page 42: ...3 8 176 12 A03 Revision 01 Date 14 11 2001 SAFETY EQUIPMENT AND PRECAUTIONS 3 ...

Page 64: ...5 4 5 START UP 176 12 A03 Revision 01 Date 14 11 2001 ...

Page 70: ...6 6 176 12 A03 Revision 01 Date 14 11 2001 6 OPERATING INSTRUCTIONS ...

Page 126: ...8 30 176 12 A03 Revision 01 Date 14 11 2001 8 MAINTENANCE ...

Page 128: ...9 2 176 12 A03 Revision 01 Date 14 11 2001 9 DECOMMISSIONING ...