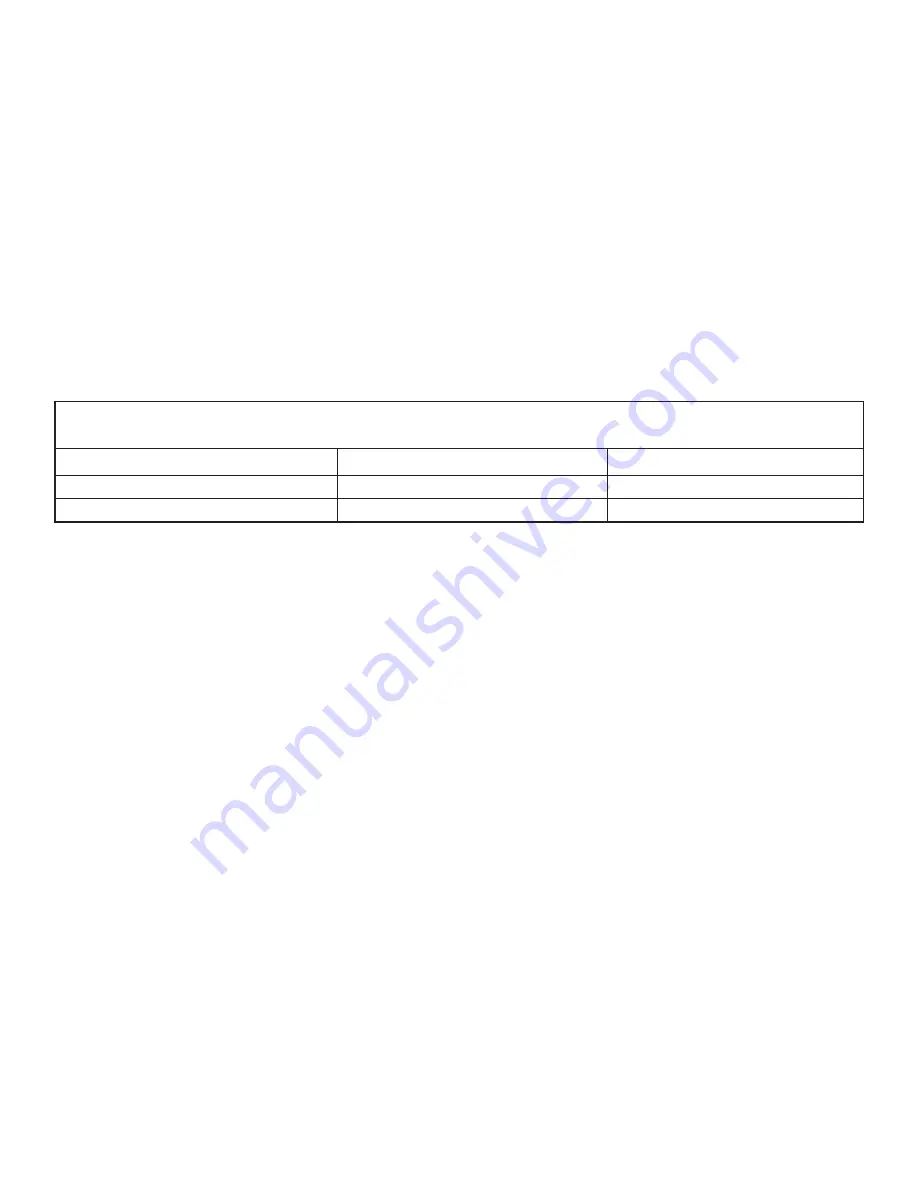

TABLE 5

7071 SERIES SHAFT RUNOUT TOLERANCES

SLEEVE FIT

COUPLING FIT

WITH SLEEVE

.002

.001

WITHOUT SLEEVE

.001

.001

25

4. Inspect the shaft (9) and sleeve (16) for

grooves or pitting, replace if any are found.

Ensure the shaft bearing fits are within the

tolerances in Table 4. Also, check that shaft

runout does not exceed the values in Table

5.

5. Inspect the bearing frame (13) and pedestal

(14) for cracks. Remove all loose foreign ma-

terial from inside the frame. Ensure that all

lubrication passages are clear.

6. Inspect stem plate (23) for pitting or wear

greater than 1/8” deep, and make sure that

the gasket surface is clean.

7. Inspect the bearing housing (6) for cracks

and pitting. Check that the bore is within the

tolerances. Replace bearing housing if bore

exceeds these tolerances.

8. Inspect the bearings (5 & 10) for contami-

nation or damage. If bearing damage is not

from normal wear, correct the problem be-

fore using pump. Do not reuse bearings.