R60-IO

User Manual

-4-

szruitech.com

3. Drive Port and Connection

3.1 Port function description

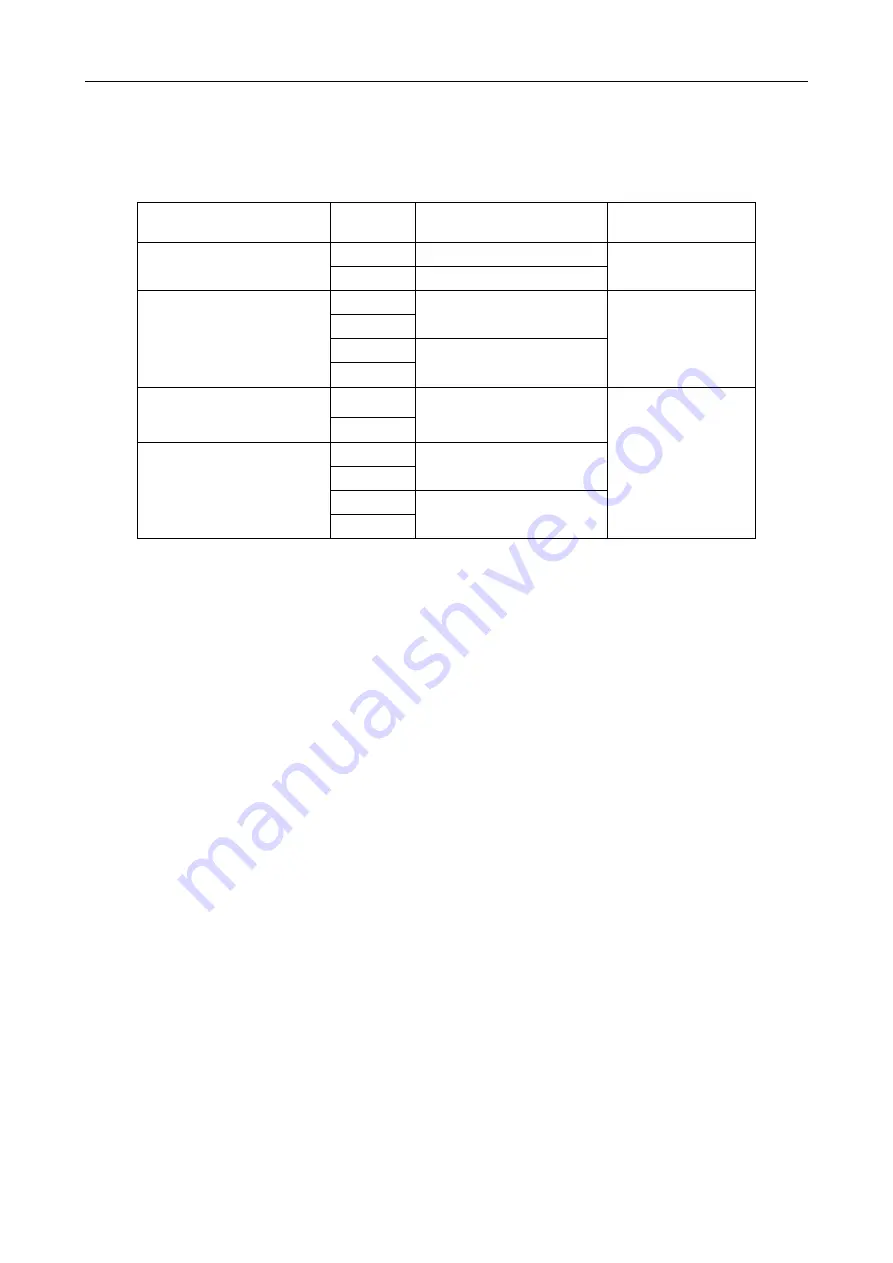

Function

Grade

Definition

Remarks

Power supply input port

AC

Input AC power supply

DC 24~48V

AC

Input AC power supply

Motor connection port

B-

connect two terminals of

motor’s phase-B winding

B+

A-

connect two terminals of

motor’s phase-A winding

A+

Potentiometer interface

ENA+

Enable control interface

3.3 ~ 24V level

compatible

ENA-

Pulse connection

IN1+

Forward trigger input

interface

IN1-

IN 2+

Reverse trigger input

interface

IN 2-

3.2 Power supply input

The power supply of the drive can be both AC power and DC power, and the input voltage range is

24V~48VDC.

Input power polarity should not be reversed!!!

The drive’s work mode is constant current control. The drive output the voltage to motor by changing the

input power into PWM chopping wave when it is working. In this case, the input power will affect the

performance of drive.

Power selection reference:

Voltage:

The stepper motor has the characteristic of torque decreasing as the motor speed increases, and the

voltage of the input power supply will affect the declining amplitude of the motor torque at high speed.

Increasing the voltage of the input power supply appropriately can increase the output torque of the

motor at high speed. And use low voltage when it is low speed required, can lower motor’s heating

appropriately.

Current:

The work of the drive is to convert the input power supply with high voltage and low current to the low

voltage and high current at both terminals of the motor winding.In this case, the current of power supply

will be lower than the motor’s.

The effects of regeneration voltage: