ROYAL ENFIELD WORKSHOP MANUAL

Section L13 Page 4

Remove this bearing first, then enter the loose

section of the spindle into the spacer and drive out

the remaining bearing by means of a hammer and

drift applied to the hexagon-headed end of the

spindle.

8. Hub Bearings

These are deep-groove single-row journal ball

bearings. The sprocket/brake drum bearing is a

Skefko RLS7, 7/8 in. i/d, by 2 in. o/d, by 9/16 in.

wide. Equivalent bearings of other makes are

Hoffmann LS9, Ransome & Marles LJ. 7/8 in.,

and Fischer LS9. The two bearings in the hub

barrel are Skefko RLS5, 5/8 in. i/d, by 1.9/16 in.

o/d, by 7/16 in. wide. Equivalent bearings of

other makes are Hoffman LS7, Ransome &

Marles LJ 5/8 in., and Fischer LS7.

9. Removal of Hub Driving Pins

To remove the six driving pins from the

aluminium fullwidth hub, first remove the hub cap

after unscrewing the three screws attaching it to

the hub. Unscrew the six Simmonds nuts and

drive out the pins.

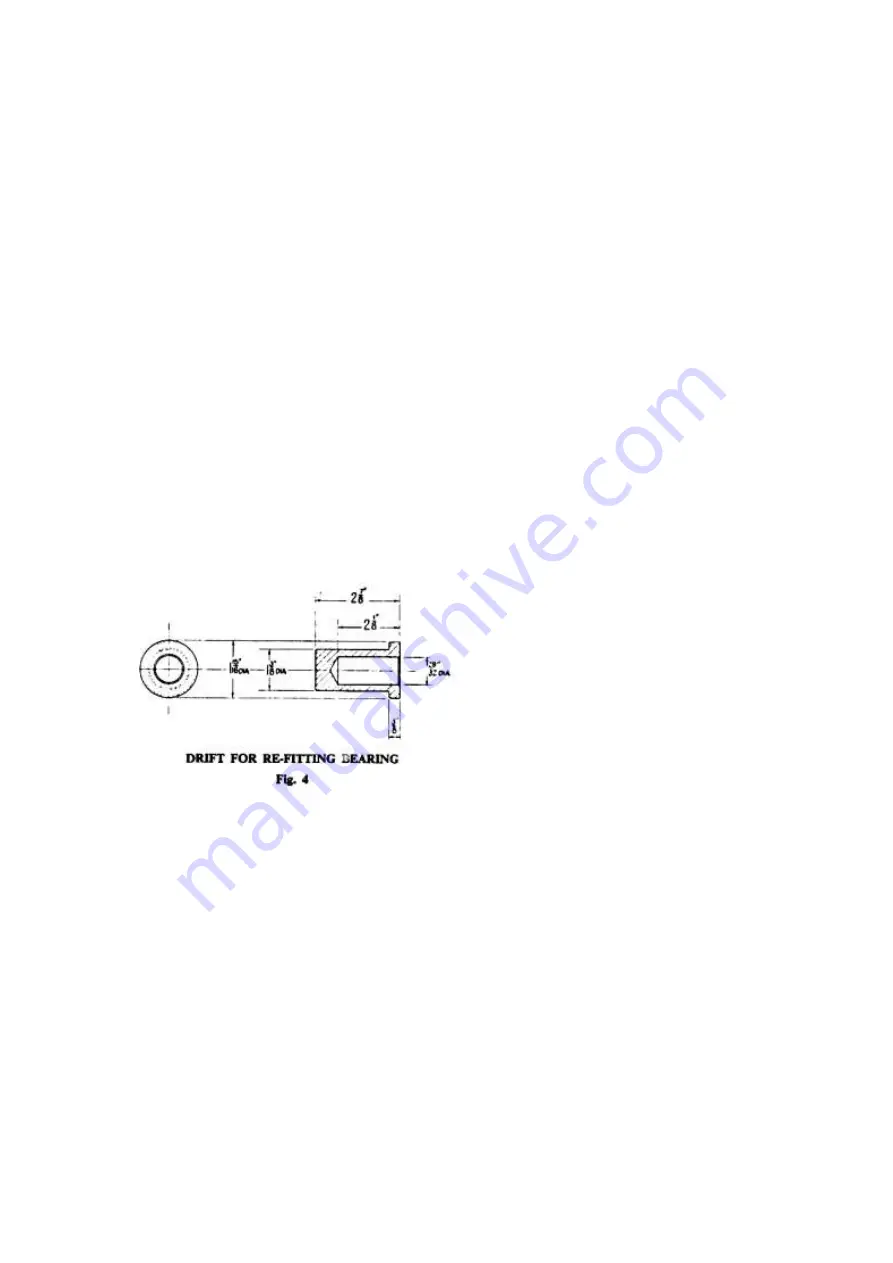

10. Refitting Ball Bearings

To refit the sprocket/brake drum bearing, use

a hollow drift as shown in Fig. 4. The bearing is

first fitted to the fixed section of the spindle ; the

spindle and bearing are then entered into the

sprocket/brake drum and driven home, preferably

under a press or using light hammer blows.

The two bearings in the hub barrel are pressed

in, using the drift part of E.4823. First assemble

the bearing into the circlip grooved end of the

barrel and fit the circlip. Replace the bearing

spacer, the slot in the spacer can be at either end of

the hubs, and assemble the second bearing,

supporting the hub on the inner race of the other

bearing. If the drift part of E.4823 is not available

it is essential that the last bearing is assembled by

applying pressure to both inner and outer races

simultaneously to avoid pre-loading the two hub

barrel bearings.

11. Reassembly of Brake Shoes, Pivot Pin and

Operating Cam into Cover Plate

No difficulty should be experienced in

carrying out these operations. Make sure that the

pivot pin is really tight in the cover plate and put

a smear of grease in the grooves of the pivot pin

and on the operating face of the cam ; also on to

the cylindrical bearing surface of the operating

cam if this has been removed. Fit the operating

lever and trunnion, 23371, on its splines in a

position to suit the extent of wear on the linings

and secure with the nut. The range of

adjustment can be extended by moving the lever

on to a different spline.

12. Centering Cam Housing

Note that the bolt holes in the cam housing,

26347, are slotted, thus enabling the brake shoe

assembly to be centered in the drum. It is not

intended that on rear brakes the cam housing

should be left free to float but the shoes should

be centred by leaving the screws, 26309 and

35140, just short of dead tight. The brake cover

plate assembly with the shoes should then be

fitted over the spindle into the brake drum and

the brake applied as hard as possible by means of

the operating lever. This will centre the shoes in

the drum. The screws should then be tightened

dead tight and secured with the locknuts. If the

shoes are not correctly centered the brake will be

either ineffective or too fierce, depending on

whether the trailing or leading shoe first makes

contact with the drum. With the brake assembly

correctly centered and the screws securing the

cam housing correctly tightened wear on both

linings should be approximately equal.

13. Final Reassembly of Hub Before

Replacing Wheel

Before replacing the felt washers which form

the grease seals, pack all bearings with grease.

Recommended greases are Castrolease LM,

Mobilgrease MP, Esso Multipurpose Grease H,

Energrease L2, Shell Retinax A or Marfak

Multipurpose 2. These are all medium heavy lime

soap or aluminium soap greases. The use of

H.M.P. greases which have a soda soap base is

not recommended as these tend to be slightly

corrosive if any damp finds it way into the hubs.

Make sure that the inside of the brake drum is

quite free from oil or grease, damp, etc. Replace

the felt washers, distance collars, the brake cover

plate assembly, speedometer drive gearbox,

www.hitchcocksmotorcycles.com

Summary of Contents for 350 BULLET 1956

Page 7: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 57: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 69: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...

Page 77: ...ROYAL ENFIELD WORKSHOP MANUAL w w w h i t c h c o c k s m o t o r c y c l e s c o m ...