EN

20

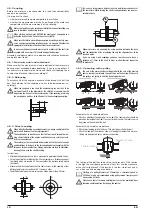

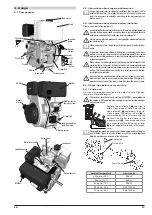

6.6. Maintenance intervals

before

each

start

after

50

hours

(Initial)

all

200

hours

(

6

month

)

all

400

hours

(

12

month

)

all

800

hours

(

24

month

)

all

1600

hours

(

36

month

)

Fuel

Refuel

Check the fuel tube for leaks

Change the fuel filter

Oil

Check oil level

Check whether any oil is leaking

Change the Oil, Clean the oil filter

Cooling

Clean cooling lamellars

Air

Clean the air filter and the filter housing

1)

Change the air filter

1)

Tubes

Replace fuel tube and (including overflow tube of the

injection nozzle)

Elektrics

only Version

"E"

Check the electric connections whether they are well

attached and in good state

Check the electric cables for scrub marks or burn

marks

Check loading state of the battery

Muffler

Check muffler and exhaust manifold for leaks

Check muffler and exhaust manifold for clogs

Check Bosch count on rated power

Screws

Check all screws (including coupled device and the

screws of the pedestal)

Check all screws which are easily accessible

Refasten cylinder head- and flywheel screws

Governing

Check easy moving of the governing lever

Readjust maximum speed

Cylinder

head

Check valve clearance

/

/

Check valve sunk deep

Change cylinder head gasket and tunnel gasket of

push-rod (beside cylinder head gasket)

/

Check compression

Change piston rings

Injection

pump

Clean injection nozzle

Check injection pressure

Check injection timing

Clean injection pump

Other

Check for abnormal noise during operation

to be done by the user

to be done by a professional

If the surrounding air is not suited due to dust, pollution or heat, an other air filter type must be installed. The standard air filter type (paper filter) is inapprop-

riate! Other air filter types are: oiled filters, cyclone separator filters. In rare or accidental cases of use the air filter must be checked and maintained straight

after usage - max. operation time between checkings is 25 working hours!