44

6.

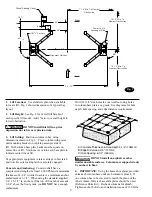

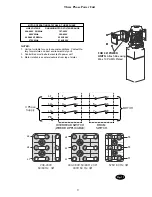

Mount switch assembly towards power unit column

as shown, Fig. 4, using (2) 1/4"-20NC x 3/4" lg. HHCS,

nuts and Star Washers.

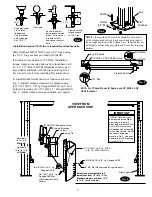

For single phase lifts:

Insert 1/4"-20NC x 2-3/4" HHCS

through pivot hole in end of switch bar. Insert opposite

end of bar through slot in switch mounting bracket. Then

secure HHCS and Switch Bar to overhead as shown,

Fig. 6a, using (2) 3/4" spacers and 1/4”-20NC Locknut.

Tighten Hex bolt leaving 1/16” gap between the spacer

and the overhead assembly.

For three phase lifts:

Remove Limit Switch cover, Fig.

6b. Insert Actuator end of Switch Bar into slot located

inside Limit Switch, Fig. 6c. A small amount of silicone

sealant on the lower part of the actuator will help hold it

in place. Insert 1/4"-20NC x 2-3/4" HHCS through pivot

hole in end of Switch Bar. NOTE which hole to use, Fig.

12. Then secure HHCS and Switch Bar to overhead as

shown, using (2) 3/4" spacers and 1/4”-20NC Locknut.

Tighten Hex bolt leaving 1/16” gap between the spacer

and the overhead assembly, Fig. 4. Replace limit switch

cover.

7.

Install overhead assembly to column extensions

with (16) 3/8"-16NC x 3/4" lg. Flanged HHCS, Flanged

Locknuts and Star Washer, Fig. 7a. To ease installation,

use the tabs on the overhead to rest it on the extensions

when installing.

Fig. 6a

Install Rubber Grommet

On Non Approach Side

of Power Unit Column

and on Approach Side

of Other Column.

Attach overhead to extension using 3/8"-16NC x 3/4"

Flanged HHCS and 3/8"-16NC Flanged Locknuts.

Use (1) 3/8" Star Lockwasher on Power Unit Side.

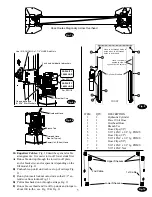

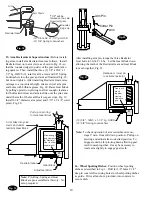

8. Power Unit:

First install (1) star washer onto one

of the (4) 5/16"-18NC x 1-1/2" HHCS.

This is very

important for grounding.

Put the (4) 5/16"-18NC x 1-1/2"

HHCS thru holes in power unit bracket using Push-Nuts to

hold in place, Fig. 8a. Mount unit with motor up to column

bracket and install (4) 5/16” star washers and 5/16” Nuts.

Install and hand tighten Branch Tee to pump until O-ring

is seated. Continue to tighten the locknut to 10-15 ft-lbs.,

or until the nut and washer bottom out against the pump

manifold.

NOTE:

You may still be able to rotate the

Branch Tee. This is acceptable unless there is seepage at

the O-ring. If so, slightly tighten the locknut.

CAUTION

Over tightening locknut may tear O-ring or

distort threads in pump manifold outlet.

9. Hoses:

Clean adapters and hose. Inspect all threads

for damage and hose ends to be sure they are crimped, Fig.

8b.

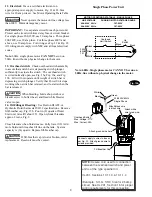

Flared Fittings Tightening Procedure

1.

Screw the fittings together finger tight. Then, using

the proper size wrench, rotate the fitting 2-1/2 hex flats

(1/3 of a revolution).

2.

Back the fitting off one full turn.

3.

Again tighten the fittings finger tight; then using a

wrench, rotate the fitting 2-1/2 hex flats (1/3 revolution).

This will complete the tightening procedure and develop a

pressure tight seal.

Adapter & Hose Installation

1.

Install Pc. (2) with hose clamps, on power unit column

side connecting it to the cylinder (1) first.

2.

Install Pc. (3) with hose clamps starting at left

column cylinder (5) and working toward the right column.

All excess hose should be at bends & inside overhead

assembly.

3.

Install Pc. (4) into power unit.

4.

Connect Pc. (2) & Pc. (3) to Tee (4).

NOTE:

Route Power Unit hose inside columns using

slots provided at column base, Fig. 9. Route Overhead

Hose in column channel on outside of column, Fig. 9, Fig.

14. Overhead hose goes through holes beside sheaves in

the overhead weldment, Fig. 7b, Fig. 9.

Fig. 6c

Fig. 7a

Fig. 6b

Place Actuator Here.

A Small Amount Of Silicone Sealant

On The Lower Part Of The Actuator

Will Help Hold It In Place.

Cradle Bar

On Actuator

Actuator

Remove Screws

And Cover