88

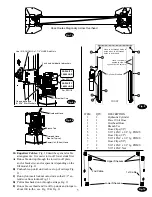

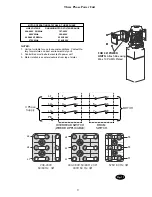

12. Electrical:

Have a certified electrician run

appropriate power supply to motor, Fig. 21 & 22. Size

wire for 20 amp circuit. See Motor Operating Data Table.

CAUTION

Never operate the motor on line voltage less

than 208V. Motor damage may occur.

IMPORTANT:

Use separate circuit for each power unit.

Protect each circuit with time delay fuse or circuit breaker.

For single phase 208-230V, use 20 amp fuse. Three phase

208-240V, use 20 amp fuse. For three phase 400V and

above, use 10 amp fuse. For wiring see Fig. 21 & Fig. 22.

All wiring must comply with NEC and all local electrical

codes.

Note:

60Hz. single phase motor

CAN NOT

be run on

50Hz. line without a physical change in the motor.

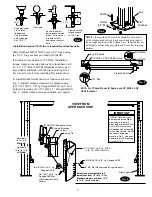

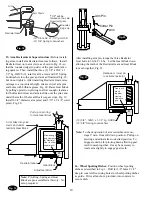

13. Overhead switch:

Check overhead switch assembly

to assure that switch bar is depressing switch plunger

sufficiently to actuate the switch. The overhead switch

is wired normally open, see Fig. 15a, Fig. 16a, and Fig.

16b. Lift will not operate until weight of switch bar is

depressing switch plunger. Verify that Power Unit stops

working when switch bar is raised, and re-starts when the

bar is released.

CAUTION

When bleeding, hold a shop cloth over

bleeder screw to buffer the air and fluid while bleeder

valve is open.

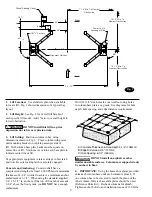

14. Oil Filling & Bleeding:

Use Dexron III ATF, or

Hydraulic Fluid that meets ISO 32 specifications. Remove

fill-breather cap, Fig. 15b. Pour in (8) quarts of fluid.

Start unit, raise lift about 2 ft. Open cylinder bleeders

approx. 2 turns, Fig. 9.

Close bleeders when fluid streams. Fully lower lift. Add

more fluid until it reaches fill line on the tank. System

capacity is (14) quarts. Replace fill-breather cap.

CAUTION

If fill-breather cap is lost or broken, order

replacement. Reservoir must be vented.

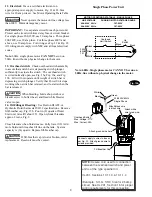

Single Phase Power Unit

MOTOR OPERATING DATA TABLE - SINGLE PHASE

LINE VOLTAGE

RUNNING MOTOR VOLTAGE RANGE

208-230V 50Hz.

197-253V

208-230V 60Hz.

197-253V

Note: 60Hz. Single phase motor CAN NOT be run on

50Hz. line without a physical change in the motor.

Overhead Switch

Max. Voltage: 277V

Max. Current: 25A

Connect supply to wires in box as

per Fig. 22. Attach ground wire to

screws provided.

Fill Breather Cap

Attach ground wire here.

208-230V 60Hz

Single Phase

Attach black wire

to black wire.

Attach white

wire to red wire.

Black

Green

White

M

230V

60Hz

1 Ø

Black

Green

White

Overhead

Limit Switch

Up

Switch

White

Black

Black

NOTE:

Assure cord used for connection

between the overhead switch and power

unit is of the type specified in:

UL201, Sections 10.1.1.3 & 10.1.1.4

(Example: SO, G, STO) Size for 25 amp

circuit. See UL 201, Section 15 for proper

wiring requirements for this connection.

Fig. 15b