2

3

2

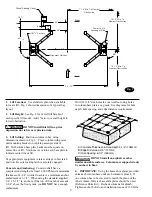

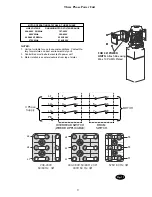

Shims

(1/2" Max.)

Nut

Flat

Washer

Anchor

Fig. 2

Fig. 3

Shim thickness MUST NOT exceed 1/2” when using

the 5-1/2” long anchors provided with the lift.

If anchors do not tighten to 150 ft-lbs. installation

torque, replace concrete under each column base with

a 6' x 6' x 6" thick 3000 PSI minimum concrete pad

keyed under and flush with the top of existing floor.

Let concrete cure before installing lifts and anchors.

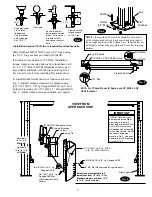

5.

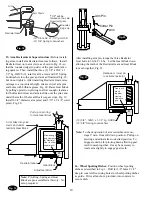

Install Rubber Grommets in extensions as shown,

Fig. 6. Install column extensions to columns using

(16) 3/8"-16NC x 3/8" lg. Flanged HHCS, Fig. 5, and

Column Ties using (8) 3/8"-16NC x 1" Flanged HHCS,

Fig. 5. Adjust column extensions plumb as required.

Installation torque of 150 ft-lbs. is required for all anchor bolts.

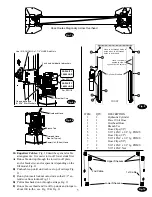

Run nut down just

below impact section

of bolt. Drive anchor

into hole until nut

and washer contact

base.

Clean hole.

Drill holes using

3/4" carbide

tipped maso-

nary drill bit per

ANSI standard

B94.12.1977

4-1/4"

Tighten nut with

Torque wrench

to 150 ft.-lbs.

2-1/4"

3-1/4"

4-1/4"

VIEW FROM

APPROACH SIDE

• All Star Washers are to

be mounted on the Right

side column to ensure

grounding of overhead limit

switch. Star Washers are

not needed when mounting

to Left Side column. Notice

the column extension

mounting, Fig. 4, and over-

head limit switch mounting

as well in Fig. 5.

IMPORTANT

Column Tie

(8) 3/8"-16NC x 3/4" Lg.

Flanged HHCS.

Column Extension

Column

(2) 1/4"-20NC x 3/4" Lg. HHCS

& (2) 1/4"-20NC Hex Nuts

(8) 3/8"-16NC x 3/8" Lg. Flanged HHCS.

(1) 3/8" Star Washer used on right side only!

Right Column

Extensions are adjustable in 6"

increments from 15' to 16'-6" for

Standard models, and from 13'-6"

to 14'-6" for LC models.

3/8"-16NC x 3/8" Lg.

Flanged HHCS(for

attaching extension to

column).

Fig. 5

Adjustable

13' -6" to 14'-6"

LC Model

Adjustable

15' to 16'-6"

Standard

(8) 3/8-16NC Flanged Locknuts

NOTE:

If more than 2 horse shoe shims are used at any

of the column anchor bolts, pack non-shrink grout under

the unsupported area of the column base. Insure shims are

held tightly between the baseplate and floor after torquing

anchors.

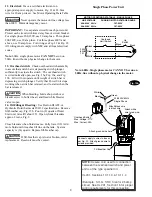

Fig. 4

(2)--3/4" Spacers

1/4"-20NC x 2-3/4" HHCS & Locknut

Star Washer

Flat Washer

Overhead Switch

1/16" Gap

NOTE: For 3 Phase lifts, use (2) Spacers and 1/4"-20NC x 2-3/4"

HHCS & Locknut