22

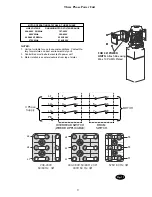

1. Lift Location:

Use architects plan when available

to locate lift. Fig. 1 shows dimensions of a typical bay

layout.

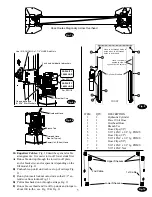

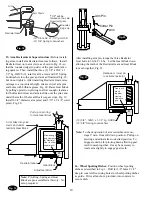

2. Lift Height:

See Fig. 4 for overall lift height of

each specific lift model. Add 1” min. to overall height to

lowest obstruction.

WARNING

DO NOT install this lift in a pit or

depression due to fire or explosion risks.

3. Lift Setting:

Position columns in bay using

dimensions shown in Fig.1. Place column with power

unit mounting bracket on vehicle passenger side of

lift. Both column base plate backs must be square on

center line of lift. Notches are cut into each base plate to

indicate center line of lift.

Use appropriate equipment to raise carriage to first latch

position. Be sure locking latch is securely engaged.

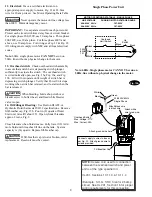

Concrete and Anchoring:

Concrete shall have a

compression strength of at least 3,000 PSI and a minimum

thickness of 4-1/4" in order to achieve a minimum anchor

embedment of 3-1/4". When using the standard supplied

3/4” x 5-1/2” lg. anchors, if the top of the anchor exceeds

2-1/4” above the floor grade, you

DO NOT

have enough

embedment.

Fig. 1

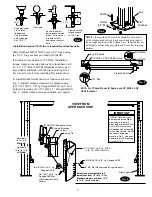

Drill (18) 3/4" dia. holes in concrete floor using holes

in column base plate as a guide. See diagrams for hole

depth, hole spacing, and edge distance requirements.

A) Concrete Thickness & Hole Depth 4-1/4" (108mm)

B) Edge Distance 4-3/4" (121mm)

C) Hole Spacing 6-1/2" (165mm)

A

B

C

C

B

C

C

CAUTION

DO NOT install on asphalt or other

similar unstable surfaces. Columns are supported only

by anchors in floor.

4. IMPORTANT:

Using the horse shoe shims provided,

shim each column base until each column is plumb. If

one column has to be elevated to match the plane of the

other column, full size base shim plates should be used

(Reference Shim Kit). Recheck columns for plumb.

Tighten anchor bolts to an installation torque of 150 ft-lbs.

H

C

A

O

R

P

P

A

C

L

Rear

Front

Lift

12' - 11"

15'– 0" Min. To

Nearest Obstruction

90

0

Power Unit to

Passenger Side

15'– 0" Min. To

Nearest Obstruction

(18)

3

/

4

" Anchors

7''– 6" Min. To Nearest

Obstruction

90

0

62

7

/

16

"

19

1

/

4

"

Wheel Spotting Dishes

6"

34"

28"

Alignment Notches