8

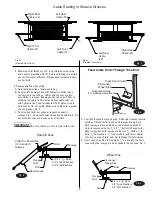

Attaching Cables

Sheave

Spacer

Sheave

Nut

Spacers

Sheave

Pin

Sheave

Yoke End

Sheave

Cover

Yoke

End

Spacers

Pinetree

Retainer

Viewed from above

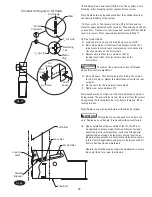

Jam Nut

Column Top

Plate

5

/

16

" Machine Screw

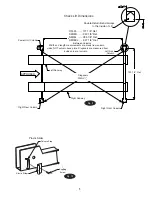

8. Adjust Cable:

Adjust all cables with lift fully lowered. Loosen cable jam nut.

Tighten adjusting nut on cable stud on top of column until

yoke end is raised

1

/

4

”. Back off adjusting nut one (1) turn.

Tighten jam nut. Do this for all four (4) cables. See Fig. 13.

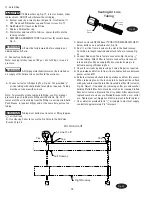

9. Power Unit:

A. Align Air Valve Bracket with holes in right side of

column bracket, Fig. 16.

B. Put four

5

/

16

” x1-

1

/

2

” lg. hex. bolts through holes in column

bracket, using push-nuts to hold in place. When using 3Ø

Control Box with push button, position mounting bracket to

the rear of the power unit bracket and attach using two (2) of

the

5

/

16

”-18NC x 1 1/2” HHCS, Fig. 16.

C. Mount power unit, with motor up, to the column bracket and

install four

5

/

16

” lock washers and nuts.

D. Run hydraulic hose from runway through slot in side of

runway to power unit output port, Fig. 17. DO NOT use Teflon

tape on hydraulic hose connections. Install and hand tighten

elbow to pump until O-ring is seated and elbow should be

oriented downward at approximately 45°,Fig. 17. Tighten

locknut to 35-40 ft. lbs.

E. Install enclosed capacity label on power unit, Fig. 17.

10. Electrical: Have a certified electrician run 230 volt

single phase 60 Hz. power supply to motor, Fig.18 and 19. Size

wire for 30 amp. circuit. See Motor Operating Data table.

Numbers 5 & 6

Refer to

Parts

Breakdown

Fig. 13

IMPORTANT

Cables must fit in slack cable arm rollers, Fig.15

Fig. 15

Fig. 14

Right Rear

(#4)

Left Front

(#1)

Left Rear

(#3)

Roping Diagram

Right Front

(#2)

Cable in Slack Cable Arm Rollers

Locking Latch

Slack Cable Arm Roller

Cable

Summary of Contents for RFL25

Page 14: ...NOTES ...

Page 15: ...NOTES ...