12

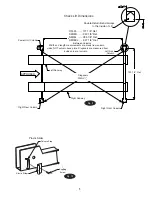

11. Fluid Filling:

CAUTION

If fill/breather cap, Fig. 17, is lost or broken, order

replacement. DO NOT substitute with a solid plug.

A. System capacity is twenty-two (22) quarts. Use Dexron III

ATF. Remove fill/breather cap and fill vent screw, Fig. 17.

B. Add fluid until it reaches the fill line.

C. Replace fill/breather cap.

D. Start motor and raise lift to full rise. Lower the lift onto the

locking latches.

E.

R

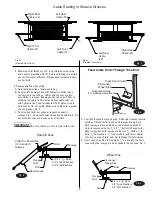

EMOVE ALIGNMENT STUDS from all four (4) column bases,

Fig. 8.

IMPORTANT

Lift must be fully lowered before changing or

adding hydraulic fluid.

12. Connecting Air Supply:

Note: Locking latches require 100 p.s.i. min to 120 p.s.i. max. air

pressure

IMPORTANT

A filter/regulator/lubricator must be installed on

air supply at lift. Failure to do so will void the warranty.

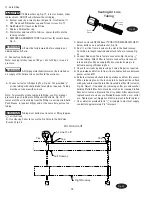

A. Connect air valve to Reducing Tee, Fig. 24. Cut provided

1

/

4

”

air line tubing with sharp blade to length as required. Tubing

must be cut square with no burrs.

Note: To assemble air line tubing into fitting, use firm, manual

pressure to push tubing into fitting until it bottoms, Fig. 23. If

removal of the air line tubing from the fitting is ever required, hold

Push Sleeve in (against fitting) and, at the same time, pull out on

tubing.

IMPORTANT

Tubing must bottom out in valve or fitting (approx.

3

/

4

”) or it will leak.

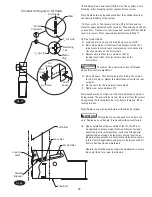

B. Use Housing Collar to secure the Air Valve to the Air Valve

Bracket, Fig. 24.

C. Attach enclosed NP280 decal (“PUSH TO RELEASE LATCHES”)

below button on air valve bracket, Fig. 16.

D. Run

1

/

4

” air line from air valve to the slot in the fixed runway.

Cut airline to length required and attach to Tee in runway, Fig.

22.

E. Connect Reducing Tee to female connector, Fig. 24, using

3

/

8

”

air line tubing. Attach filter to female connector and connect

into existing facility air supply. Make sure plastic plug is in

bottom opening of Reducing Tee.

F. Check for air leaks by depressing air valve. Repair as required.

G. Use provided cable ties to tie air line to hydraulic hose between

power unit and lift.

H. Actuate air valve and check latch operation on all four (4) corners.

When releasing locks, the locking latch should pull back flush

with yoke end to clear the latch bar located in all four (4) columns,

Fig. 24. Adjust, if required, by removing cotter pin and washer

holding Slotted Bracket on locking latch and screwing Slotted

Bracket in to move it toward the air cylinder. After adjustment,

replace washer and secure Slotted Bracket with a

new

cotter

pin. Tighten jam nut. Apply Loctite® to jam nut to hold in place.

I. Use cable ties provided to tie

3

/

8

” air supply to electrical supply

conduit at approximately 2’-0” intervals.

Fig. 22

Fig. 23

Tee

Right Runway

Tee

Tee

Left Runway

Air Line To Lift

Air Line in Lift

Seating Air Line

Tubing

Air Line

Tubing

Push

Sleeve

Summary of Contents for RFL25

Page 14: ...NOTES ...

Page 15: ...NOTES ...