2

Required Clearances

Read and understand Installation Instructions completely

before starting with lift installation.

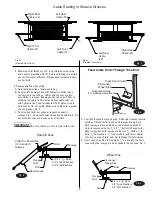

1. Lift Location: Use architects plan when available to locate lift.

Fig. 1 shows dimensions of a typical bay layout. For power

unit at right front, rotate lift 180°, leaving ramp/chocks and

wheel stops in original position. Lift floor area should be

level.

WARNING

DO NOT install on asphalt or other similar

unstable surfaces. Columns are supported only by anchors in

floor.

Note: If runway extensions are used, an additional 3’–0” of

clearance must be added to end with extensions.

2. Ceiling or overhead clearance must be 80” plus height

of tallest vehicle.

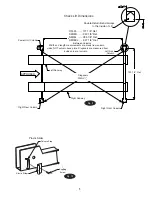

3. Estimating Column Shim requirements:

In the following section, the terms “highest” and

“lowest” refer to elevation of floor.

A. Mark locations where lift columns will be

positioned in bay.

B. Place target at column positions and record

readings, Fig. 2.

C. Find the highest of the four (4) locations. Find the

difference between the reading at each of the

remaining three (3) columns and the highest

reading.

D. The difference is the estimated amount of shim

thickness needed at each column.

Fig. 2

Fig. 1

APPROACH

C

L

Left

Runway

Right

Runway

Rear Clearance

Rear Clearance (Min. 5'-6" for SM30's, 8'-6" for

RFL25's) = rear overhang of longest v required

work space

Front Clearance

8'–0" Min. To

Nearest

Obstruction

8'–0" Min. To

Nearest

Obstruction

FRONT

REAR

Front Clearance = front overhang of

longest v required work space

Transit

Estimation Shim Requirements

Target

Dimension at highest position minus other

position = shim thickness required

Summary of Contents for RFL25

Page 14: ...NOTES ...

Page 15: ...NOTES ...