Rotar Giga 75-100 - Cod.197AA3900 - Rev.03 - 05/2007

14

14

14

14

14

12

Rotar 75

Rotar 100

P max. 8 bar

56 Hz

63 Hz

P max. 10 bar

55 Hz

62 Hz

1

2

3

4

H

G

I

L

MAINTENANCE

AFTER THE FIRST 2,000 OPERATING HOURS AND THEN

EVERY 4,000 OPERATNG HOURS

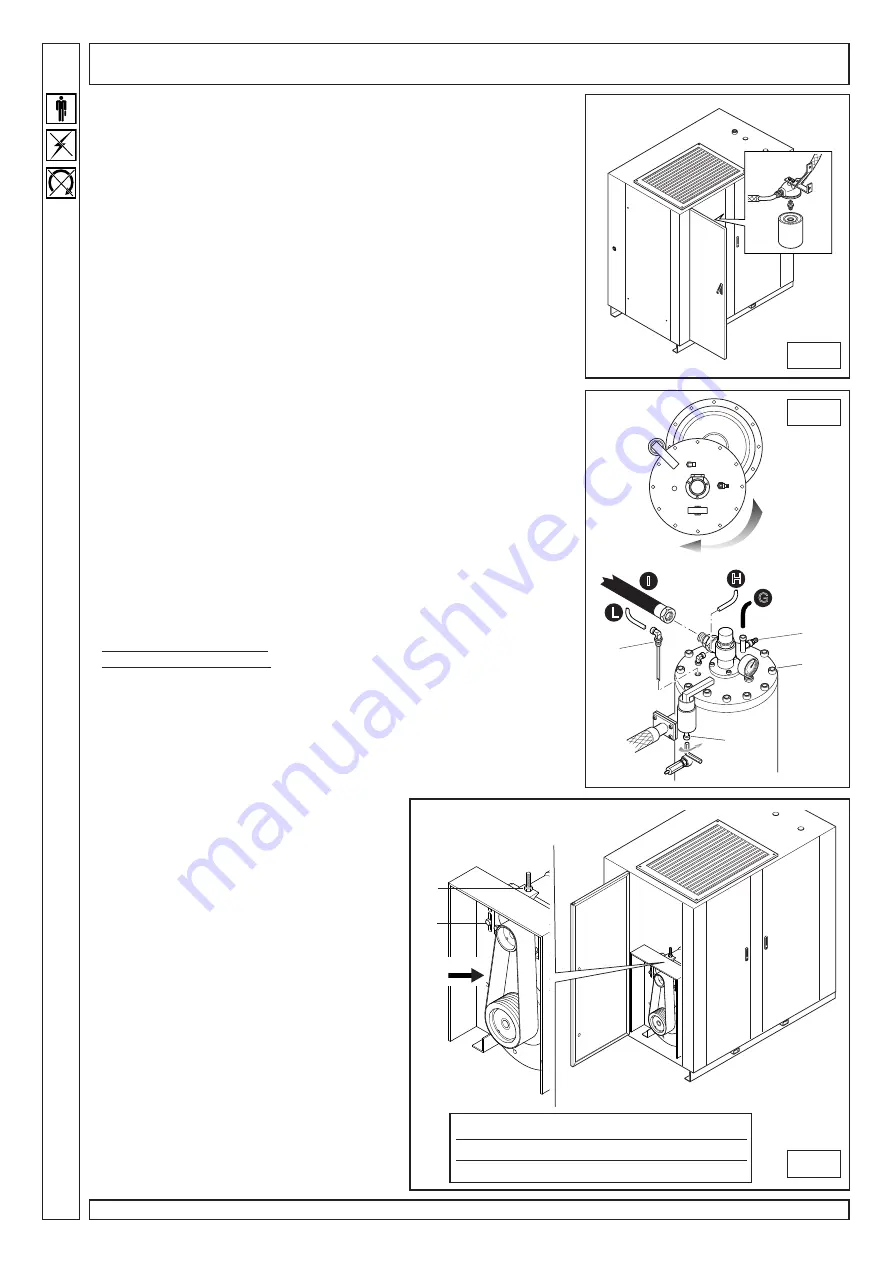

Change OIL FILTER (fig.10)

•

Change the filter at any oil change with the oil separator tank not under

pressure. Always bleed all air off the cock (1) (see fig. 11).

•

Open door (E) (see fig.7). The oil filter is inside the middle stand, as shown

in the figure.

•

Undo the filter with the proper tool. Replace with a new filter. Always apply a

film of oil on filter edge and gasket before tightening.

Change OIL SEPARATOR FILTER (fig.11)

•

Open door (F) (see fig.7) and bleed all air off the tank through cock (1).

•

Disconnect tubes G, H, I and L.

•

Fully undo fitting (2) and remove copper drain tube.

•

Undo and remove screws (3).

•

Turn screw (4) anti-clockwise with a hex. wrench, until lifting oil separator

cover by about 0.5 cm.

•

Manually turn the cover to reach tank inside.

•

Remove oil separator filter (using a proper tool) and replace with a new

filter. Also replace the two seal rings and make sure they are properly seated.

EVERY 10000 HOURS

DRIVE BELT tension (fig.12)

To perform this check you need a special measurement instrument that that

provides a precise indication of the level of tension of the belt by means of a

frequency measurement.

Proceed as follows:

•

Open the door (D) (see fig.7).

•

Bring the microphone of the measurement instrument up to the belt at the

point indicated with “test” (about halfway) and strike the belt with a spanner.

•

Read the value detected by the instrument and if it is different from the

values indicated on the table, adjust the tension:

Higher value = belt too tight

Lower value = belt too loose

•

Loosen screws A to allow the attachment plate on which the screw unit is

fixed to slide, and use adjusting nut B to adjust the tension.

Turn the nut anti-clockwise to increase tension and clockwise to reduce tension.

Re-tighten screws A and check the frequency value; if necessary, repeat the

operation until the desired value has been reached.

EVERY 20000 HOURS

Replace the DRIVE BELT (fig.12)

Proceed as follows:

•

Open the door (D) (see fig.7) and remove the

protective panel of the belt/pulley compartment.

•

Loosen screws A to allow the attachment plate

on which the screw unit is fixed to slide.

•

Loosen nut B until the belt is completely

relaxed and remove it.

•

Fit the new belt and tighten it as described in

the previous section.

Also replace

•

Compressor seal ring

•

Tank safety valve

10

11

A

B

Test

Summary of Contents for Giga 100

Page 2: ......