Controller functions

Version 1

RES-403

Page 33

6.11

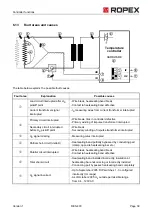

System monitoring/alarm output

To increase operating safety and to avoid faulty heatsealing, this controller incorporates special hardware and

software features that facilitate selective fault detection and diagnosis. Both the external wiring and the internal

system are monitored.

These features assist the operator in identifying the cause of abnormal operations.

A system fault is reported or differentiated by means of the following indications.

A.)

Red "ALARM" LED on the controller

three states:

1.

Blinks fast (4Hz)

The AUTOCAL function should be executed (error codes 104…106, 211, 302, 303; up to September 2005:

error codes 8+9).

2.

Blinks slowly (1Hz)

The system configuration is incorrect and the zero calibration (AUTOCAL function) was unsuccessful

(

section 5.11 "Controller configuration" on page 16). It corresponds to error codes 110…114 (up to Sep-

tember 2005: error codes 10…12).

3.

Lit continuously:

This indicates that a fault is preventing the controller from being started (error codes 101…103, 107, 108,

201…203, 307, 308, 801, 9xx; up to September 2005: error codes 1…7).

As a rule, it refers to an external wiring fault.

B.)

Alarm relay (relay contact terminals 5+6):

This contact is set in the factory as follows:

•

OPEN

in operating states A.1) and A.2), but closed if a "START" signal is activated in one of these states.

•

CLOSED

in operating state A.3)

If the alarm relay is configured opposite to the factory setting (

section 5.11.3 "Configuration of the alarm relay"

on page 18), these states are reversed.

C.)

Error code output via the 0

…

10VDC analog

output (terminals 14+15):

Since a temperature indication is no longer necessary if a fault occurs, the analog output is used to dis-

play error messages in the event of an alarm.

13 voltage levels (up to September 2005: 12 voltage levels) are offered for this purpose in the 0…10VDC range,

each of which is assigned an error code (

section 6.12 "Error messages" on page 34).

If a state that requires AUTOCAL occurs – or if the controller configuration is not correct – (error codes 104…106,

111…114, 211, 302, 303; up to September 2005: error codes 8…12), the signal at the analog output jumps back

and forth at 1Hz between the voltage value which corresponds to this error and the end of the scale (10VDC, i.e.

300°C or 500°C). If the "START" signal is activated in one of these states, the voltage value does not change any

more.

An alarm can only be reset by switching the controller off and then on again.

Invalid error messages may appear when the controller is switched off owing to the undefined oper-

ating state. This must be taken into account when they are evaluated by the higher-level controller

(e.g. a PLC) in order to avoid false alarms.

!

!