Installation

Page 18

RES-403

Version 1

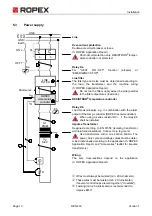

5.11.3 Configuration of the alarm relay

If the plug-jumper is not inserted - or if it is incorrectly inserted - an error message appears when

the controller is switched on (

section 6.12 "Error messages" on page 34).

If the "Alarm output opened by alarm/PC CONFIGURATION" position is selected (as of October 2005), the

behavior of the alarm output can be configured in more detail by means of the ROPEX visualization software

(

see section 6.10 "Diagnostic interface/visualization software (as of October 2005)" on page 32).

5.12

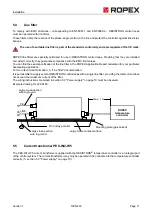

Replacing and "burning in" the heatsealing band

5.12.1 "Burning in" the heatsealing band

The heatsealing band is a key component in the control loop, since it is both a heating element and a sensor. The

geometry of the heatsealing band is too complex to be discussed at length here. We shall therefore only refer to

a few of the most important physical and electrical properties:

The measuring principle applied for this system necessitates a heatsealing band alloy with a suitable temperature

coefficient TCR. Too low a TCR leads to oscillation or uncontrolled heating.

When heatsealing bands with a higher TCR are used, the controller must be calibrated for this.

The first time the heatsealing band is heated to approximately 200…250°C, the standard alloy undergoes a once-

only resistance change (burn-in effect). The cold resistance of the heatsealing band is reduced by approximately

2…3%. However, this at first glance slight resistance change results in a zero point error of 20…30°C. The zero

point must therefore be corrected after a few heating cycles, i.e. the AUTOCAL function must be repeated.

The burn-in effect described here does not occur if the heatsealing band has already been thermally pretreated

by the manufacturer.

An overheated or burned-out heatsealing band must no longer be used because the TCR has been

altered irreversibly.

One very important design feature is the copper or silver-plating of the heatsealing band ends. Cold ends allow

the temperature to be controlled accurately and increase the life of the teflon coating and the heatsealing band.

0

5

1

2

3

4

6

7

8

9

Alarm relay contact

opened by alarm/

PC-CONFIGURATION.

Alarm relay contact

closed by alarm.

(factory setting)

CONFIGURATION

ALARM OUTPUT

DE-ENERGIZED / PC

AT ALARM

ENERGIZED

!

!