Performing Advanced Setup of the Media

15

Chapter 1 Fully Utilizing the Machine

4.

Press [ ], [ ], [ ], or [ ] when the following screen appears .

SCAN: 000.0mm

FEED: 000.0mm

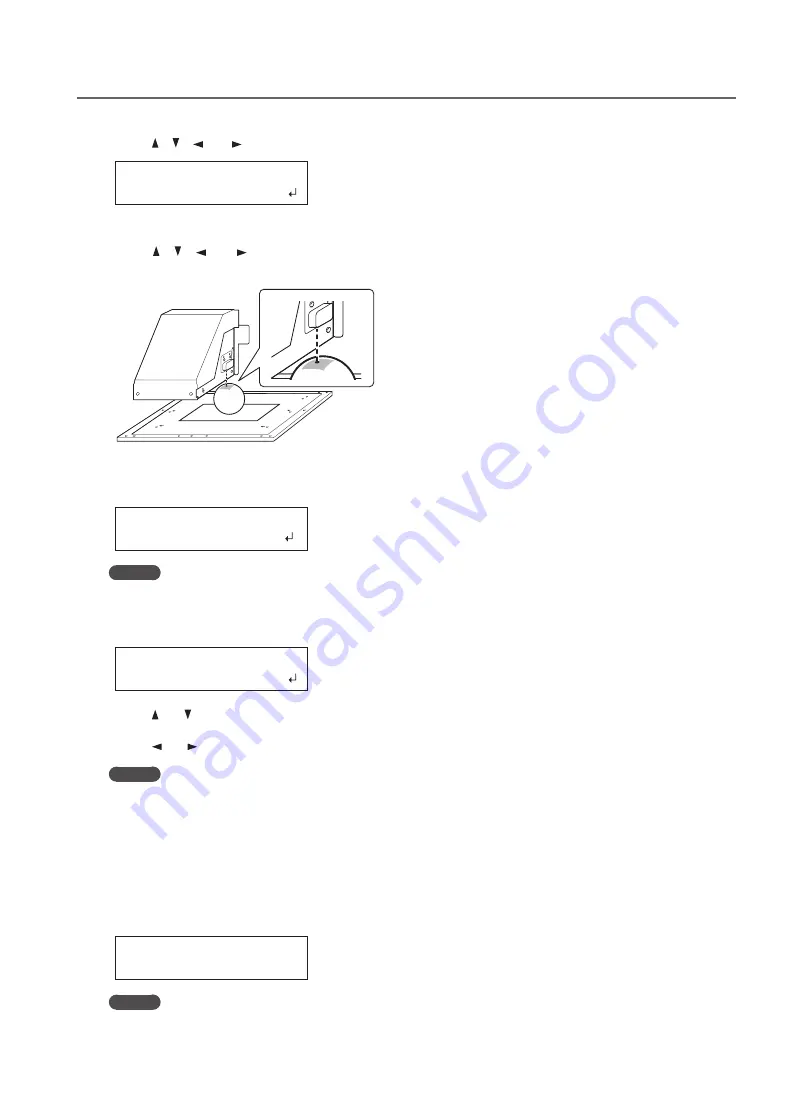

The flat table moves to the rear, the print heads move to above the flat table, and the laser pointer turns on .

5.

Press [ ], [ ], [ ], or [ ] to move the laser pointer until it points to the center position of the area you

want to print .

6.

Press [ENTER] .

The print heads return to the home position .

WIDTH: 000.0mm

LENGTH:000.0mm

MEMO

When the media comes into contact with the head gap sensor, the screen shown in the figure appears and

the setup is canceled . Perform operations again from "2 . Setting the Height of the Media Automatically"

(First Step Guide) or "Setting the Height of the Media Manually" (P . 8) .

CHECK TABLE

HEIGHT

7.

Press [ ] or [ ] to enter the length of the area you want to print .

8.

Press [ ] or [ ] to enter the width of the area you want to print .

MEMO

For a test print, set "WIDTH" to 80 mm (3 .2 in .) or more and "LENGTH" to 70 mm (2 .8 in .) or more . An error

will occur and test prints cannot be performed if the area is smaller than this .

9.

If the front cover is open, close it .

10.

Press [ENTER] .

The print area is specified . The print heads return to the home position .

Make sure the "W" (width), "L" (length), and "H" (height) values on the menu screen are as intended .

W:508mm L:330mm

H:100.0mm

MEMO

If you want to use the print area specified here for the next printing operation, switch "SET AT SETUP" (P .

11) to "DISABLE ." With this setting, you can set up the media without setting the print area and base

position .