Creating an SRP Player File

39

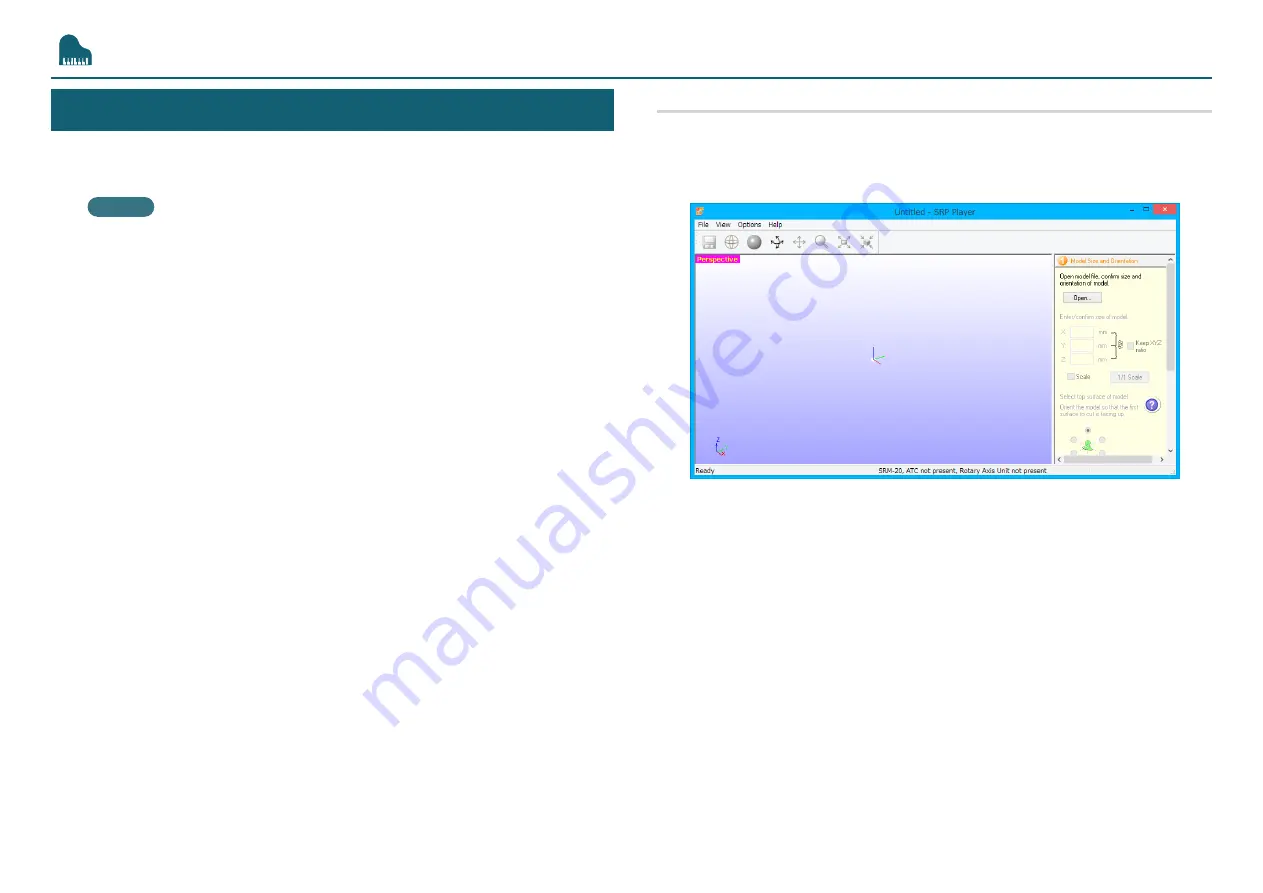

STEP 1: Determine the Size and Orientation of the Model

Load an IGES, DXF (3D), or STL format file to set the size and orientation .

MEMO

For details on how to change the settings, see the

[Help]

.

"

Procedure

1.

Start SRP Player.

"

"

"The Name and Function of the Tool bar"

●〇〇〇

Summary of Contents for monoFab SRM-20

Page 18: ...18 VPanel Operation Panel QuitVPanel Click ...

Page 33: ...SRP Player 33 5 Click 6 Select the unit of length and click ...

Page 99: ...Cutting One Side Cutting 99 Completing Cutting Click ...

Page 146: ...Appendix Specifications 147 External View 147 Main Specifications 151 ...

Page 149: ...Specifications 149 Machine Interior Side Face 140 100 2 M3x0 5 140 100 2 M3x0 5 Unit mm ...

Page 152: ...R4 171006 FA01218 ...