- 24 -

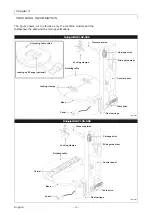

Rotoplat DW 108 - 508 “PLURIBALL”

Rotoplat DW-C 108 - 508 “PLURIBALL”

C

14C214009

D

E

E

14C214010

Rotoplat DW 108 - 508

Rotoplat DW-C 108 - 508

English

Chapter 3

TECHNICAL INFORMATION

–

“Pluriball” reel carriage unit (C)

:

suited for wrapping on corners

or sides, using Pluriball orsimilar

reels. It is equipped with “quick

load” film and a safety device to

stop the carriage.

–

Rotating table (ø1800):

towrap larger than standardloads.

–

Sliding guide mast (2800 - 3100 mm)

: to wrap taller than standard

loads.

‒

Locking half flange:

Locking device on the worktable

of the product to be wrapped.

The product locks on the worktable,

by pushing one of the two half

flanges

(E)

with a foot.

To unlock press the foot switch

(D)

.