51 • Setting Basic Operational Parameters in the Config Menu

Date, Time, and Date/Time Format

Do the following to view or change the docking station’s date, time, or date/time

format.

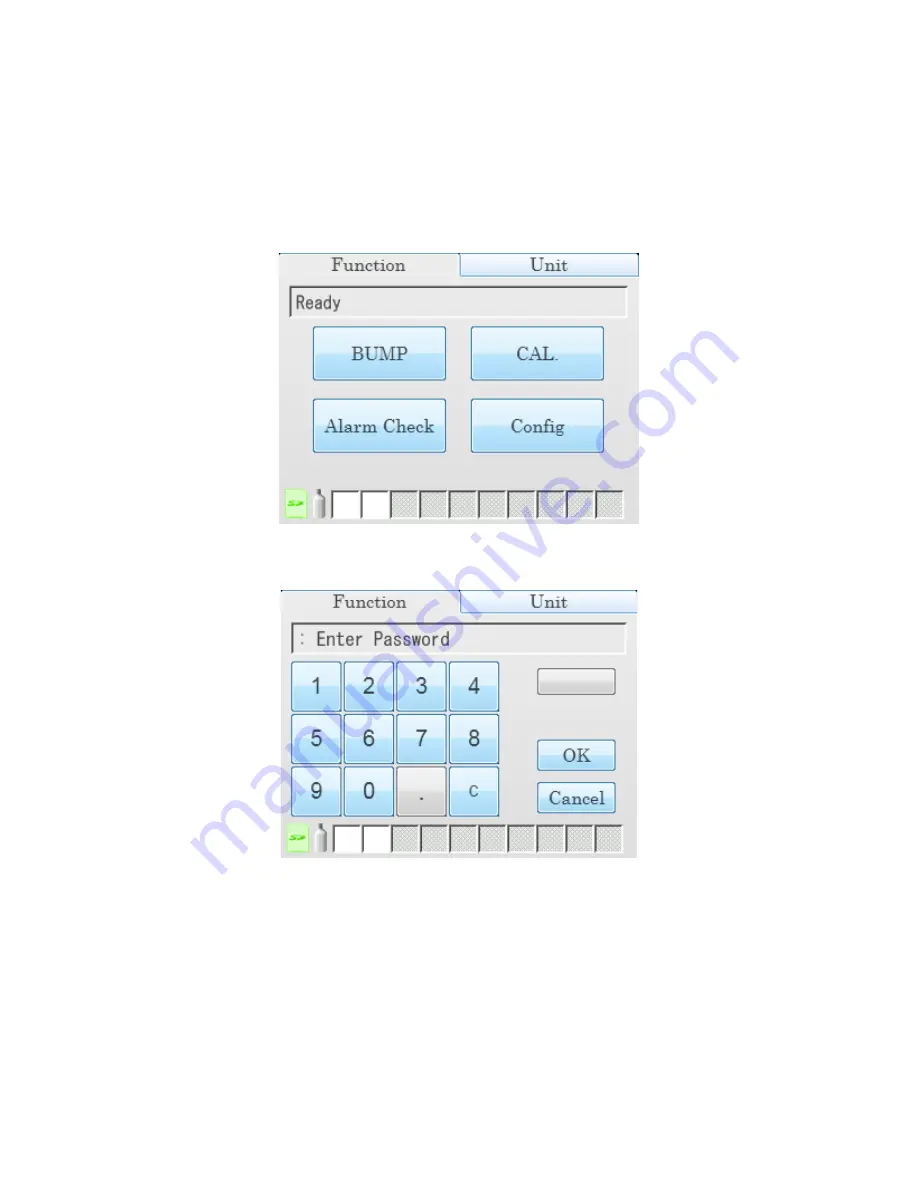

1 . Turn on the SDM-6000 system. The Function Tab will be displayed on a single

station system’s screen or on the master station’s screen in a multi-station

system.

2 . Press the Config button. If Password is set to on (factory setting is off), you will

be prompted for a password. Enter the password and press OK to continue.