22

PUB. NO. FASTRAXC FEBRUARY 2008

FASTRAX

™

VIRTUAL VISION INSTALLATION

NOTE: Virtual Vision is standard on Freezer / Cooler doors

provided with the Insulmax curtain. There will be a

motion sensor mounted on each side of the door,

as well as 2 red LED light bars on each side of the

opening on both sides. The motion sensors will

detect motion on the opposite side of the curtain to

warn oncoming traffic of a possible pedestrian or

forklift on the opposite side.

1.

If door is equipped with Thermal Air Seal Step Down

Transformer junction box, plug in Virtual Vision cable. If

not, there will be a separate junction box strictly for the

Virtual Vision.

2.

Virtual Vision light bar assemblies should be located on

each side of the doorway and in clear view of oncoming

traffic. They should be installed approximately 3' off the

floor, adjacent to the doorway (e.g. goal posts or wall) and

in a location that is protected from potential impact

damage,

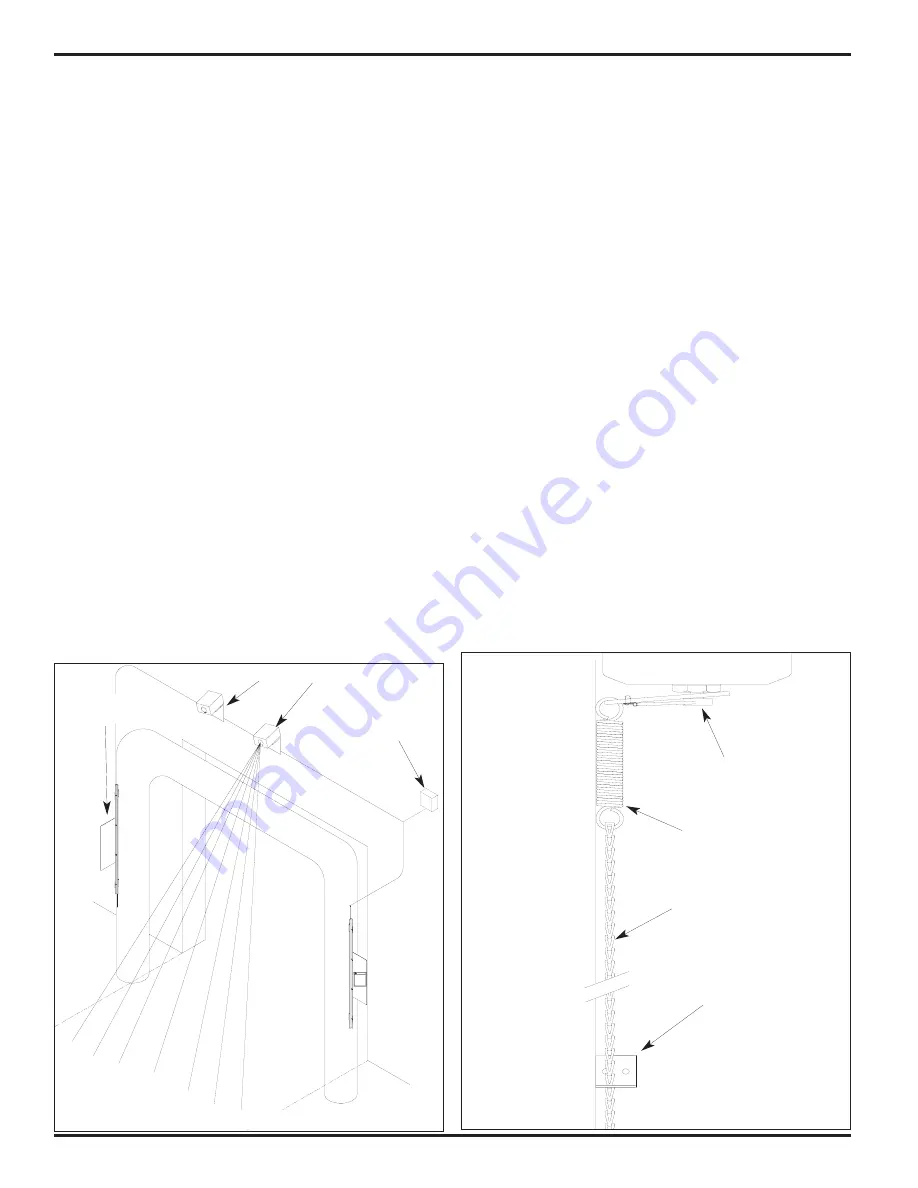

Figure 39.

3.

Motion sensors can be installed above the opening on

Radial doors or off to the side if Vertical, 45° Tilt, High or

Standard lift.

4.

Sensors should be programmed for a 2 second hold time

and bi-directional detection.

5.

Direct sensors so they DO NOT extend beyond the width

of the door.

6.

Plug cables together and wire into control box.

7.

To avoid cross talk when changing the settings on the

Virtual Vision or activation sensors when using the remote

controls, Rite-Hite offers the following three options:

a)

The BEA remote control allows you to set a unique

security code for each sensor. That way, you would enter

the code for the sensor you are interested in changing,

and it will only change the settings for that sensor. To

accomplish this, temporarily disconnect the activation

sensor(s) from its power supply (at the I-COMM), use the

remote to set a security code (e.g. "1111") for the Virtual

Vision sensor(s), then power up all sensors. The

activation sensor will have the default security code

"0000" for its settings, and the Virtual Vision sensor will

have its new security code when changing its settings

(use unlock/lock sequence). There should be no cross-talk

with the remote's instructions when using this approach.

Make sure to record these values for future reference.

b)

If you do not wish to use security code settings, you can

simply power down one unit (at the I-COMM) while setting

the other unit, and then do the same thing with the other

unit. This is similar to option "a", although if you want to

make subsequent changes to the settings, you would

need to go through the power down procedure again.

c)

If you do not wish to power down the units or use security

settings, you can physically cover one of the units while

programming the other unit. Any opaque material (e.g.

cardboard) should work. However, with units typically

mounted high above the opening, this may be difficult.

BRAKE RELEASE INSTALLATION

1.

If door is equipped with the brake release option, see

Figure 40.

2.

Remove brake handle and attach brake release bracket to

the bottom of the brake.

3.

Attach spring to the bracket and chain to the spring.

4.

Install wall mount bracket to wall, so that it will hold chain

in place, to release brake. Trim excess chain as required.

VIRTUAL VISION

Do Not Enter

On Red Light

Personnel Or Equipment

May Be Present On The

Other Side Of The Door

WARNING

FIGURE 39 - VIRTUAL VISION

FIGURE 40 - BRAKE RELEASE

Pull Chain

Wall Mount Bracket

Brake

Spring

Brake Release Bracket

Virtual Vision Sensor

Virtual Vision

Junction Box

Opposite Side

Virtual Vision Lite

Bar Assembly

Motion Sensor

Summary of Contents for FASTRAX

Page 13: ...PUB NO FASTRAXC FEBRUARY 2008 13 FASTRAX i COMM LOGIC CHART FIGURE 22 LOGIC CHART...

Page 32: ...32 PUB NO FASTRAXC FEBRUARY 2008 FASTRAX VIRTUAL VISION ELECTRICAL WIRING...

Page 36: ...36 PUB NO FASTRAXC FEBRUARY 2008 FASTRAX RADIAL ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 37: ...PUB NO FASTRAXC FEBRUARY 2008 37 FASTRAX VERTICAL ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 38: ...38 PUB NO FASTRAXC FEBRUARY 2008 FASTRAX STANDARD LIFT ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 39: ...PUB NO FASTRAXC FEBRUARY 2008 39 FASTRAX HIGH LIFT ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 40: ...40 PUB NO FASTRAXC FEBRUARY 2008 FASTRAX 45 TILT ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 41: ...PUB NO FASTRAXC FEBRUARY 2008 41 FASTRAX FR VERTICAL ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 42: ...42 PUB NO FASTRAXC FEBRUARY 2008 FASTRAX FR STANDARD ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 43: ...PUB NO FASTRAXC FEBRUARY 2008 43 FASTRAX FR HIGH LIFT ARCHITECTURAL DRAWING D O O R SYSTEM...

Page 44: ...44 PUB NO FASTRAXC FEBRUARY 2008 FASTRAX FR 45 TILT ARCHITECTURAL DRAWING D O O R SYSTEM...