- 18 -

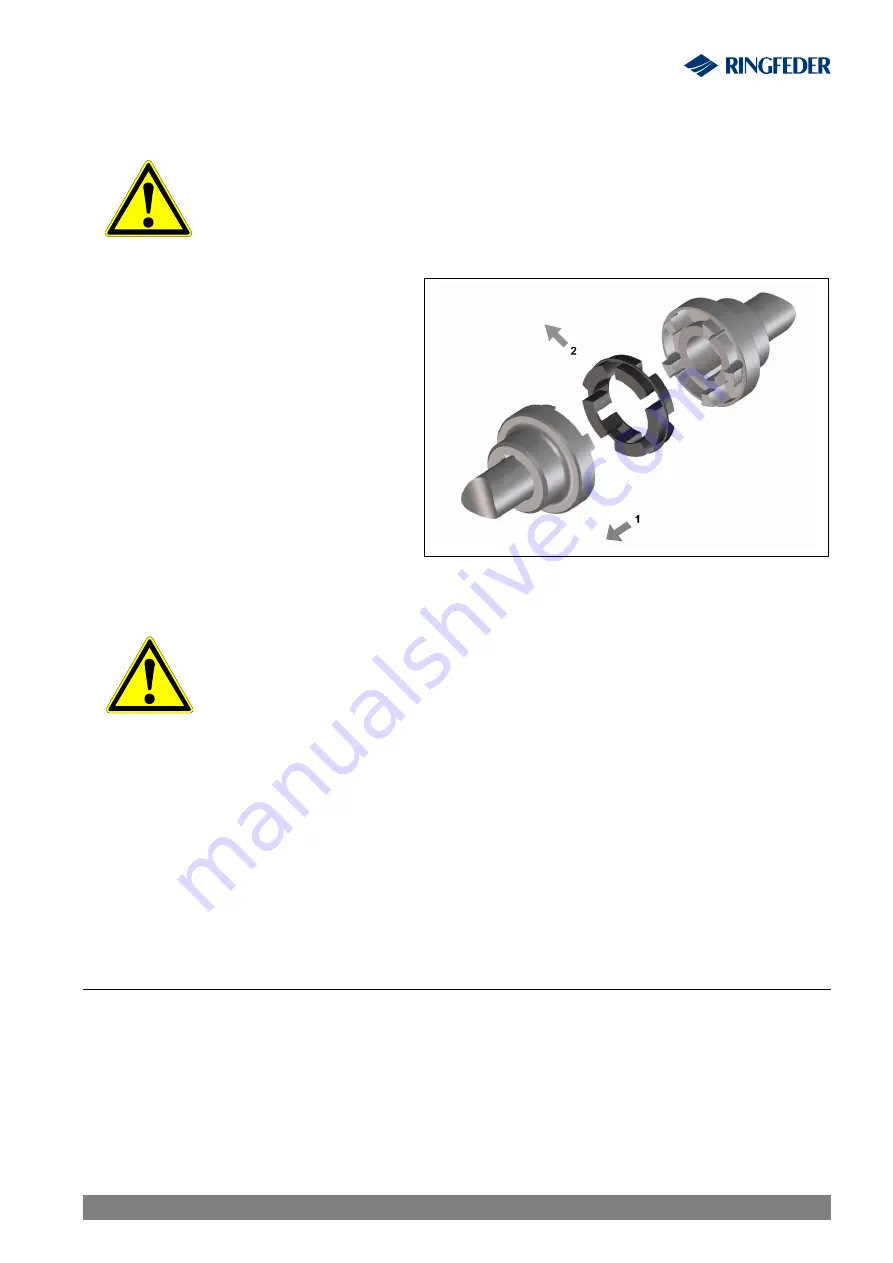

Fig. 10

10.3 Changing the elastic intermediate ring

Injury hazard!

Switch-off the drive before all work on the coupling!

Secure the drive against unintentional switching on and rotating!

•

Pull back a shaft with mounted

coupling hub (Figure 10, Pos. 1).

•

Remove the intermediate ring

(Figure 10, Pos. 2).

•

For easier mounting, the new

intermediate ring can be provided

with a slip additive before introduc-

tion (e.g. Talcum)

•

insert a new intermediate ring

•

Push the coupling halves together

again.

•

Adjust the coupling according to the

following specifications in “8 Cou-

pling adjustment".

Warning!

Before commissioning the plant, install all protective devices

against unintentional touching of free rotating parts.

To avoid sparks coverings in stainless steel should be used.

The coverings must fulfil at least the demands of protection type

IP2X.

The covering is to be so designed that it does not deposit dust

onto the coupling parts.

The covering must not touch the coupling or influence it in its

function.

When using accessories and spare parts which were not originally manufactured by

RINGFEDER POWER TRANSMISSION

, no liability or guarantee for any damages

will be accepted.

11 Waste Disposal

The waste disposal has to occur according to the specific regulations of the respective user

country.

RINGFEDER

®

TNM E

BAWN 001-

GBR

-1