- 7 -

7 Assembly

7.1 Pay attention before the assembly

•

Danger of injuries!

•

Disconnect the drive before carrying out any work on the coupling!

•

Secure the drive against unintentional re-start and rotation!

-

Incorrectly tightened bolts can cause serious personal injuries and

property damages!

•

In compliance with accident prevention regulations, you are

obliged to protect all freely rotating parts by means of permanently

installed guards/ covers against unintentional contact and falling

down objects.

•

To avoid sparks, the covers for couplings used in explosive

atmospheres should be made of stainless steel!

•

As a minimum, the covers have to fulfil the requirements of protec-

tion type IP2X.

•

The covers have to be designed to prevent dust from depos

iting on

the coupling.

•

The cover must not contact the coupling or impair the proper

function of the coupling.

•

Make sure that the speeds, torques and ambient temperatures as stated in chapter 6

‘Technical Data’ are not exceeded.

•

The maximum permissible bore diameters must not be exceeded.

•

Check whether the shaft-hub connections safely transmit the occurring operating torques.

•

The standard tolerance of

RINGFEDER

®

TNM

for finish bores is fit H7.

•

Standard keyways comply with DIN 6885, sheet 1.

•

Check the dimensions and tolerances of shafts, hub bores, keys and keyways.

•

Set screws as required.

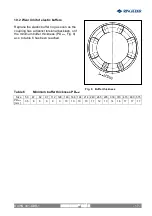

7.2 Finished borehole

For the completion of the finished borehole in a coupling hub, pay attention to following

procedure:

•

Clean the coupling hub of preservatives.

•

Tighten the coupling hub to the surfaces marked with

and carefully align the coupling

hub.

•

The indicated values in table 1 for ød

1max

are valid for a parallel key connection according

to DIN 6885/1 and must not be exceeded.

•

Choose the borehole fit so that during the union with the shaft tolerance a wringing fit

and/or an interference fit as for example at H7/m6 is carried out.

•

Provide a setscrew for axial securing on the hub back above the parallel key slot.

In the case of other shaft hub connections, consultation with

RINGFEDER POWER

TRANSMISSION

is necessary.

RINGFEDER

®

TNM E

BAWN 001-

GBR

-1