9

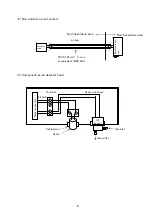

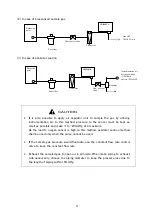

(2) In case of intrinsically safe system

You can build the intrinsically safe system by adding

optional zener barrier between detector head and indicator/alarm unit.

①

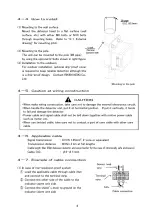

Lead the applicable cable through cable inlet and connect to the terminal strip.

② Connect the optional zener barrier between this unit and indicator/alarm unit at

non-hazardous area. (See below fig.)

③ Connect the other side of the cable to the indicator/alarm unit side.

④ Connect the shield

’

s drain wire to ground on the indicator/alarm unit.

・

Do not alter, nor remodel the parts, etc.

・

Use the circuit breaker as for the power of indicator/alarm unit. Also it shall be mounted

nearby indicator/alarm unit and be specified that it is for power interruption of

indicator/alarm unit.

・

Ground the zener barrier separately corresponding to the A-class grounding with ground

resistance of 10Ω or less.

・

Use the specified cable.

・

For system installation, operation and maintenance, take care not to damage the intrinsically

safe design.

・

The power of the indicator/alarm unit shall be turned on after completion of all wirings. If

each wiring is carried out in the power on condition, short-circuit between terminals or an

electrical shock may be occurred.

* NOTE

When wiring, read the operating manual for the connected indicator/alarm unit.

WARNING

CAUTION

!

GD-F4A-SC-A

1

3

2

4

D

e

t

e

c

t

o

r

h

e

a

d

I

n

d

i

c

a

t

o

r

/

a

l

a

r

m

u

n

i

t

Zener

barrier

(

MTL7728ac

)

max. 2km

max. 250m(CVVS 1.25mm

2

)

Hazardous

zone

Non-hazardous

zone

Connection cable

Connection

cable

Summary of Contents for GD-F4A-SC-A

Page 1: ...Oxygen Gas Detector Head GD F4A SC A Operating Manual PT2 152 PT2E 2510...

Page 6: ......

Page 11: ......

Page 19: ......

Page 24: ......

Page 26: ...Manual Log Rev Amendment Issue data 0 First issue 2018 2 9...