17

20170392

GB

Installation

6.4

Operating position

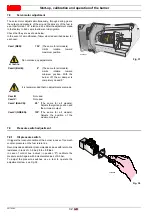

6.5

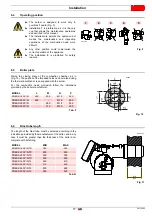

Boiler plate

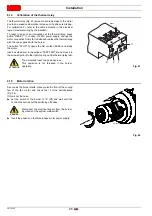

Pierce the closing plate of the combustion chamber, as in

(Fig. 10). The position of the threaded holes can be marked using

the thermal insulation screen supplied with the burner.

For the combustion head protrusion follow the indications

provided by the boiler manufacturer.

Tab. F

6.6

Blast tube length

The length of the blast tube must be selected according to the

indications provided by the manufacturer of the boiler, and in any

case it must be greater than the thickness of the boiler door

complete with its fettling.

Tab. G

ATTENTION

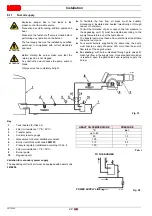

The burner is designed to work only in

positions

1

and

4

(Fig. 9).

Installation

1

is preferable, as it is the only

one that allows the maintenance operations

as described in this manual.

The installation

4

permits the operation but

makes the maintenance and inspection

operations of the combustion head more

difficult.

DANGER

Any other position could compromise the

correct operation of the appliance.

The installation

5

is prohibited for safety

reasons.

Fig. 9

2

3

4

5

1

20172679

MODEL

L

M

N

P

PRESS 140 P/N

260

230

M 14

225

PRESS 200 P/N

260

-

M 16

255

PRESS 300 P/N

-

260

M 18

300

PRESS 450 P/N

-

310

M 20

350

Fig. 10

S9890

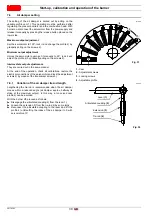

MODEL

MIN

MAX

PRESS 140 P/N TC

180

300

PRESS 200 P/N TC

200

340

PRESS 300 P/N TC

200

350

PRESS 450 P/N TC

250

400

PRESS 140 P/N TL

290

410

PRESS 200 P/N TL

310

450

PRESS 300 P/N TL

330

480

PRESS 450 P/N TL

380

530

20172681

MIN

MAX

Fig. 11

Summary of Contents for PRESS 140 P/N

Page 2: ...Translation of the original instructions...

Page 57: ...55 20170392 GB Appendix Electrical panel layout 0 1 2 2 2 0 DIRECT START UP...

Page 58: ...20170392 56 GB Appendix Electrical panel layout 0 1 1 1 STAR TRIANGLE START UP...

Page 59: ...57 20170392 GB Appendix Electrical panel layout 0 1 0...