57

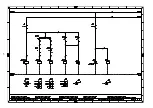

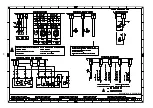

KEY TO ELECTRICAL LAYOUT

A1

-

Control box

B1

-

Internal output power regulator RWF

B2

-

External output power regulator RWF

BA

-

DC input 0...20 mA, 4...20 mA

BA1

-

DC input 0...20 mA, 4...20 mA for modifying the

remote setpoint

BP

-

Pressure probe

BP1

-

Pressure probe

BR

-

Remote setpoint voltage divider

BT1

-

Thermocouple probe

BT2

-

Probe Pt100 with 2 wires

BT3

-

Probe Pt100 with 3 wires

BT4

-

Probe Pt100 with 3 wires

BTEXT

-

External probe for the climatic compensation of the

setpoint

BV

-

DC voltage input 0...1 V, 0...10 V

BV1

-

DC voltage input 0...1 V, 0...10 V for modifying the

remote setpoint

CN1

-

Ionisation probe connector

F1

-

Fan motor thermal cut-out

F3

-

Auxiliary fuse

H1

-

Signal light for burner on

H2

-

Signal light for motor trip

H3

-

Signal light for burner lock-out

ION

-

Ionisation probe

KL1

-

Direct start and star/delta starter line contactor

KT1

-

Star-powered/delta-powered starter /delta contactor

KS1

-

Star-powered/delta-powered starter /star-powered

contactor

KST1

-

Star-powered/delta -powered starter timer

K1

-

Fan on voltage free contact relay

K2

-

Motor lock-out voltage free contact relay

K3

-

Burner lock-out voltage free contact relay

K6

-

Burner on voltage free contact relay

MV

-

Fan motor

PA

-

Air pressure switch

PE

-

Burner ground

PGMin

-

Minimum gas pressure switch

PGM

-

Maximum gas pressure switch

RS

-

Remote lock-out reset button

S1

-

Emergency stop push-button

S2

-

Switch for following operations:

off-automatic-manual

S4

-

Button for: power increase/reduction

SH3

-

Burner reset button and lockout warning

SM

-

Servomotor

TA

-

Ignition transformer

TL

-

Limit pressure switch/thermostat

TR

-

Control pressure switch/thermostat

TS

-

Safety pressure switch/thermostat

Y

-

Gas adjustment valve + gas safety valve

YVPS

-

Gas leak detection control device

X1

-

Main supply terminal strip

X2

-

RWF terminal strip

XAUX

-

Auxiliary terminal strip

XPGM

-

Maximum gas pressure switch connection plug

XPGM1

-

Maximum gas pressure switch connection plug

XRWF

-

Output power regulator RWF terminal strip

XS

-

Flame detectors connector

XSM

-

Air and gas servomotors connector

NOTE

Wiring must be performed by qualified personnel in

accordance with the regulations in force in the

country of destination.

Riello S.p.a. declines all responsibility for changes or wiring

performed in any way other than that illustrated in these dia-

grams.

LÉGENDE SCHÉMAS ELECTRIQUE

A1

-

Coffret de sécurité

B1

-

Régulateur de puissance RWF intérieur

B2

-

Régulateur de puissance RWF extérieur

BA

-

Entrée avec courant DC 0...20 mA, 4...20 mA

BA1

-

Entrée avec courant DC 0...20 mA, 4...20 mA pour

décalage valeur de consigne à distance

BP

-

Sonde de pression

BP1

-

Sonde de pression

BR

-

Potentiomètre valeur de consigne à distance

BT1

-

Sonde avec thermocouple

BT2

-

Sonde Pt100 à 2 fils

BT3

-

Sonde Pt100 à 3 fils

BT4

-

Sonde Pt100 à 3 fils

BTEXT

-

Sonde externe pour la compensation climatique de

la valeur de consigne

BV

-

Entrée avec tension DC 0...1 V, 0...10 V

BV1

-

Entrée avec tension DC 0...1 V, 0...10 V pour déca-

lage valeur de consigne à distance

CN1

-

Connecteur sonde d'ionisation

F1

-

Relais thermique moteur ventilateur

F3

-

Fusible auxiliaire

H1

-

Signal lumineux brûleur allumé

H2

-

Signal lumineux blocage moteur

H3

-

Signal lumineux blocage brûleur

ION

-

Sonde d'ionisation

KL1

-

Contacteur de démarrage direct et de ligne démar-

reur étoile/ triangle

KT1

-

Contacteur triangle démarreur étoile/triangle

KS1

-

Contacteur étoile démarreur étoile/triangle

KST1

-

Temporisateur démarreur étoile/triangle

K1

-

Relais sortie contacts propres ventilateur allumé

K2

-

Relais sortie contacts propres blocage moteur

K3

-

Relais sortie contacts propres blocage brûleur

K6

-

Relais sortie contacts propres brûleur allumé

MV

-

Moteur ventilateur

PA

-

Pressostat air

PE

-

Mise à la terre brûleur

PGMin

-

Pressostat gaz mini

PGM

-

Pressostat gaz maxi

RS

-

Bouton de déblocage à distance

S1

-

Bouton arrêt d’urgence

S2

-

Sélecteur: éteint / automatique / manuel

S4

-

Sélecteur: augmentation / diminution puissance

SH3

-

Bouton de déblocage du brûleur et signal de blo-

cage

SM

-

Servomoteur

TA

-

Transformateur d’allumage

TL

-

Thermostat/ Pressostat de limite

TR

-

Thermostat/ Pressostat de réglage

TS

-

Thermostat/ Pressostat de sécurité

Y

-

Vanne de réglage gaz + vanne de sécurité gaz

YVPS

-

Dispositif de contrôle d’étanchéité vannes

X1

-

Plaque à bornes alimentation principale

X2

-

Plaque à bornes pour kit RWF

XAUX

-

Plaque à bornes auxiliaire

XPGM

-

Connecteur pressostat gaz maxi

XPGM1

-

Connecteur pressostat gaz maxi

XRWF

-

Plaque à bornes régulateur de puissance RWF

XS

-

Connecteur détecteurs flamme

XSM

-

Connecteur servomoteurs air et gaz

REMARQUE

Les branchements électriques doivent être

effectués par du personnel qualifié, conformément

aux normes en vigueur dans le pays de destination.

Riello S.p.A. décline toute responsabilité en cas de modifica-

tions ou de branchements autres que ceux représentés sur ces

schémas.

Summary of Contents for 887T

Page 2: ......

Page 49: ...47...

Page 50: ...48 0 1 1 1...

Page 51: ...49 0 0 0...

Page 52: ...50 0 1 1 1...