25

GASDRUCK

Die Tab. A gibt die minimalen Strömungsverluste

entlang der Gasversorgungsleitung in Abhängig-

keit von der Höchstleistung des Brenners an.

Die in Tab. A angeführten Werte beziehen sich

auf:

–

Erdgas G 20 Hu 9,45 kWh/Sm

3

(8,2 Mcal/

Sm

3

)

–

Erdgas G 25 Hu 8,13 kWh/Sm

3

(7,0 Mcal/

Sm

3

)

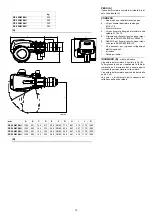

Spalte 1

Strömungsverlust Flammkopf.

Gasdruck, am Anschluss P1(A) Abb. 22 gemes-

sen mit:

•

Brennkammer auf 0 mbar

•

Auf Höchstleistung laufender Brenner;

•

Flammkopf mit Einstellung gemäß Dia-

gramm von Seite 20.

Spalte 2

Strömungsverlust Gasdrossel bei maximaler

Öffnung: 90°.

Zur Ermittlung der ungefähren Brennerleistung

im Betrieb auf der Höchstleistung des Brenners:

–

Vom Gasdruck am Anschluss P1(A) Abb. 22

den Druck in der Brennkammer abziehen.

–

In der Tab. A des betreffenden Brenners den

dem Subtraktionsergebnis nächsten Druck-

wert ablesen.

–

Die entsprechende Leistung links ablesen.

Beispiel RS 400/M BLU mit Erdgas G20:

Betrieb auf Höchstleistung

Gasdruck am Anschluss P1(A) Abb. 22

= 21,7 mbar

Brennkammerdruck

= 2 mbar

21,7 - 2 = 19,7 mbar

Einem Druck von 19,7 mbar, Spalte 1 entspricht

in der Tab. A eine Leistung von 3500 kW.

Dieser Wert dient als erste Näherung; der tat-

sächliche Durchsatz wird am Zähler abgelesen.

Um stattdessen den am Anschluss P1(A) Abb.

22 notwendigen Gasdruck zu ermitteln, nach-

dem die Höchstleistung festgelegt wurde, bei der

der Brenner arbeiten soll:

–

in der Tab. A des betreffenden Brenners die

dem gewünschten Wert nächste Leistungs-

angabe ablesen.

–

Rechts, in Spalte 1, den Druck am An-

schluss P1(A) Abb. 22 ablesen.

–

Diesen Wert mit dem angenommenen

Druck in der Brennkammer addieren.

Beispiel RS 400/M BLU mit Erdgas G20:

Gewünschte Höchstleistung: 3500 kW

Gasdruck bei einer Leistung von 3500 kW

= 19,7 mbar

Brennkammerdruck

= 2 mbar

19,7 + 2 = 21,7 mbar

Am Anschluss P1(A) Abb. 22 erforderlicher

Druck.

GAS PRESSURE

Tab. A indicates the minimum pressure drops

along the gas supply line, depending on the max-

imum burner output.

The values shown in Tab. A refer to:

–

Natural gas G 20 NCV 9.45 kWh/Sm

3

(8.2

Mcal/Sm

3

)

–

Natural gas G 25 NCV 8.13 kWh/Sm

3

(7.0

Mcal/Sm

3

)

Column 1

Pressure drop on combustion head.

Gas pressure measured at the test point P1(A)

pag. 22, with:

•

Combustion chamber at 0 mbar;

•

Burner working at maximum output;

•

Combustion head adjusted as in page 20.

Column 2

Pressure loss at gas butterfly valve with maxi-

mum opening: 90°.

Calculate the approximate maximum output of

the burner in this way:

–

subtract the combustion chamber pressure

from the gas pressure measured at test

point P1(A) pag. 22.

–

Find, in the table Tab. A related to the burner

concerned, the pressure value closest to the

result of the subtraction.

–

read the corresponding output on the left.

Example for RS 400/M BLU with G20 natural

gas:

Maximum output operation

Gas pressure at test point P1(A) pag. 22

= 21.7 mbar

Pressure in combustion chamber

= 2 mbar

21.7 - 2 = 19.7 mbar

A pressure of 19.7 mbar, column 1, corresponds

in the table Tab. A to an output of 3500 kW.

This value serves as a rough guide; the effective

output must be measured at the gas meter.

To calculate the required gas pressure at test

point P1(A) pag. 22, set the MAX output required

from the burner operation:

–

find the nearest output value in the table

Tab. A for the burner in question.

–

read, on the right (column 1), the pressure at

the test point P1(A) pag. 22.

–

Add this value to the estimated pressure in

the combustion chamber.

Example for RS 400/M BLU with G20 natural

gas:

Required burner maximum output operation:

3500 kW

Gas pressure at an output of 3500 kW

= 19.7 mbar

Pressure in combustion chamber

= 2 mbar

19.7 + 2 = 21.7 mbar

Pressure required at test point P1(A) pag. 22.

PRESSION DU GAZ

Le Tab. A indique les pertes de charge mini-

males sur la ligne d’alimentation en gaz en fonc-

tion de la puissance maximale du brûleur.

Les valeurs indiquées dans le Tab. A corres-

pondent à:

–

Gaz naturel G 20 PCI 9,45 kWh/Sm

3

(8,2 Mcal/Sm

3

)

–

Gaz naturel G 25 PCI 8,13 kWh/Sm

3

(7,0 Mcal/Sm

3

)

Colonne 1

Perte de charge tête de combustion.

Pression gaz mesurée à la prise P1(A) pag. 22,

avec:

•

Chambre de combustion à 0 mbar

•

Brûleur fonctionnant à la puissance maxi-

male;

•

Tête de combustion réglée comme indiqué à

la pag. 20.

Colonne 2

Perte de charge du papillon gaz avec ouverture

maximale: 90°.

Pour connaître la puissance maximale approxi-

mative à laquelle le brûleur fonctionne:

–

Soustraire de la pression du gaz à la

prise P1(A) pag. 22 la pression de la

chambre de combustion.

–

Repérer la valeur la plus proche du résultat

obtenu sur le Tab. A concernant le brûleur

considéré.

–

Lire la puissance correspondante sur la

gauche.

Exemple pour RS 400/M BLU avec gaz naturel

G20:

Fonctionnement à la puissance maximale

Pression de gaz à la prise P1(A) pag. 22

= 21,7 mbar

Pression chambre de combustion

= 2 mbar

21,7 - 2 = 19,7 mbar

À une pression de 19,7 mbar, colonne 1, il cor-

respond sur le Tab. A une puissance de

3500 kW.

Cette valeur sert de première approximation; il

faut mesurer le débit effectif sur le compteur.

Pour connaître la pression de gaz nécessaire sur

la prise P1(A) pag. 22, une fois établie la puis-

sance MAX. à laquelle on veut faire fonctionner

le brûleur:

–

Trouver la valeur de puissance la plus

proche à la valeur voulue dans le Tab. A

concernant le brûleur concerné.

–

Lire sur la droite, colonne 1, la pression à la

prise P1(A) pag. 22.

–

Ajouter à cette valeur la pression estimée

dans la chambre de combustion.

Exemple pour RS 400/M BLU avec gaz naturel

G20:

Puissance MAX. désirée: 3500 kW

Pression de gaz à une puissance de 3500 kW

= 19,7 mbar

Pression chambre de combustion

= 2 mbar

19,7 + 2 = 21,7 mbar

Pression nécessaire à la prise P1(A) pag. 22.

Summary of Contents for 887T

Page 2: ......

Page 49: ...47...

Page 50: ...48 0 1 1 1...

Page 51: ...49 0 0 0...

Page 52: ...50 0 1 1 1...