23

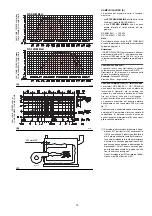

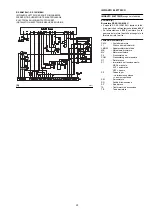

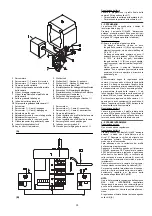

ELEKTROANSCHLÜSSE

Gemäß Norm EN 60 335-1 biegsame Kabel ver-

wenden:

• falls unter PVC-Mantel mindestens den Typ

H05 VV-F verwenden.

• falls unter Gummimantel mindestens den Typ

H05 RR-F verwenden.

Alle mit der Klemmenleiste 9)(A) des Brenners

zu verbindenden Kabel sind durch die entspre-

chenden Kabeldurchgänge zu führen.

Die Kabeldurchgänge können auf verschiedene

Arten genutzt werden. Als Beispiel führen wir

die folgenden Arten auf:

1- Pg 13,5

Dreiphasenspeisung

2- Pg 11

Einphasenspeisung

3- Pg 11

TL-Regler

4- Pg 9

TR-Regler oder Fühler (RWF40)

5- Pg 13,5

Gasventile

6- Pg 13,5

Gasdruckwächter oder Dichtheits-

kontrolle VPS

7- Pg 11

Bohren, falls man wünscht, noch

einen Anschlusstutzen einzuset-

zen

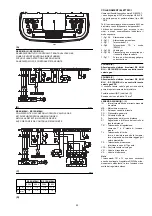

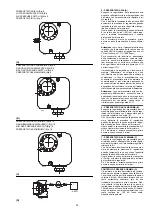

SCHEMA (B)

Elektrischer Brenneranschluß RS 68/M BLU -

RS 120/M BLU ohne Dichtheitskontrollein-

richtungen.

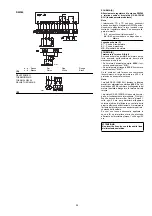

SCHEMA (C)

Elektrischer Brenneranschluß RS 68/M BLU -

RS 120/M BLU mit Dichtheitskontrolleinrich-

tungen VPS.

Die Dichtheitskontrolle der Gasventile erfolgt

umgehend vor jedem Brennerstart.

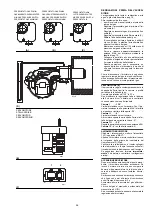

Sicherungen Schemen (B-C), siehe Tab. (D).

Nicht angegebener Kabelquerschnitt: 1,5 mm

2

.

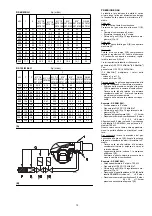

ZEICHENERKLÄRUNG SCHEMEN (B) - (C)

IN

- Schalter für das manuelle Ausschalten

des Brenners

MB

- Klemmbrett Brenner

XP

- Stecker für die Dichtheitskontrolleinrich-

tung

PG

- Gas-Minimaldruckwächter

PS

- Entriegelungsschalter

S

- Fernmeldung Störabschaltung

S1

- Fernmeldung Störabschaltung Dicht-

heitskontrolle

TR

- Regelung:

steuert 1. und 2. Betriebsstadium

TL

- Regelung:

schaltet den Brenner aus, wenn die Tem-

peratur oder der Kesseldruck den festge-

legten Wert überschreiten.

TS

- Sicherheitsregelung:

tritt bei Defekt an TL in Aktion.

VPS - Dichtheitskontrolle der Gasventile

VR

- Regelventil

VS

- Sicherheitsventil

Merke

Wenn das RWF40 für den modulierenden

Betrieb angeschlossen ist, sind die Fernsteue-

rungen TR und TL nicht erforderlich, da deren

Funktionen vom RWF40 übernommen werden.

ELECTRICAL CONNECTIONS

Use flexible cables according to EN 60 335-1

Regulations:

• if in PVC sheath, use at least H05 VV-F

• if in rubber sheath, use at least H05 RR-F.

All the wires to connect to the burner terminal

strip 9)(A) must enter through the supplied fair-

leads.

The fairleads and hole press-outs can be used

in various ways; the following lists show one

possible solution:

1- Pg 13,5

Three-phase power supply

2- Pg 11

Single-phase power supply

3- Pg 11

Remote control device TL

4- Pg

9

Remote control device TR or

probe (RWF40)

5- Pg 13,5

Gas valves

6- Pg 13,5

Gas pressure switch or gas valve

leak detection control device

7- Pg 11

Open the hole, if a pipe union is to

be added

LAYOUT (B)

Electrical connection RS 68/M BLU - RS 120/

M BLU burners without leak detection con-

trol device.

LAYOUT (C)

Electrical connection RS 68/M BLU - RS 120/

M BLU burners with VPS leak detection con-

trol device.

Gas valve leak detection control takes place

immediately before every burner start-up.

Fuses layouts (B) and (C), see table (D).

Cross-section when not indicated: 1,5 mm

2

.

KEY TO LAYOUTS (B) - (C)

IN

- Burner manual stop switch

MB

- Burner terminal strip

XP

- Plug for leak detection control device

PG

- Min. gas pressure switch

PS

- Lock-out reset button

S

- Remote lock-out signal

S1

- Remote lock-out signal of leak detection

control device

TR

- High-low mode load remote control sys-

tem:

controls operating stages 1 and 2.

TL

- Load limit remote control system:

shuts down the burner when the boiler

temperature or pressure reaches the

preset value.

TS

- Safety load control system:

operates when TL is faulty.

VPS - Leak detection control device

VR

- Adjustment valve

VS

- Safety valve

N.B.

The TR and TL load controls are not required

when the RWF40 is connected, as their function

is performed by the RWF40 itself.

BRANCHEMENTS ELECTRIQUES

Utiliser des câbles flexibles selon la norme EN

60 335-1:

• si en gaine PVC, au moins type H05 VV-F

• si en gaine caoutchouc, au moins type H05

RR-F.

Tous les câbles à raccorder au porte-bornes

9)(A) du brûleur doivent passer par les passe-

câbles. L'utilisation des passe-câbles et des

trous prédécoupés peut se faire de plusieurs

façons; à titre d'exemple nous indiquons l'une

de ces possibilités:

1- Pg 13,5

Alimentation triphasée

2- Pg 11

Alimentation monophasée

3- Pg 11

Télécommande TL

4- Pg

9

Télécommande TR ou sonde

(RWF40)

5- Pg 13,5

Vannes gaz

6- Pg 13,5

Pressostat gaz ou contrôle d'étan-

chéité vannes gaz

7- Pg

11

Percer, si l'on veut ajouter un

presse-étoupe

SCHEMA (B)

Branchement électrique brûleur RS 68/M

BLU - RS 120/M BLU sans dispositif de con-

trôle d'étanchéité.

SCHEMA (C)

Branchement électrique brûleur RS 68/M

BLU - RS 120/M BLU avec dispositif de con-

trôle d'étanchéité VPS.

Le contrôle d'étanchéité des vannes se fait juste

avant chaque mise en marche du brûleur.

Fusibles schemas (B-C), voir tab. (D).

Section câbles non indiquée: 1,5 mm

2

.

LEGENDE SCHEMAS (B) - (C)

IN

- Interrupteur électrique pour arrêt manuel

brûleur

MB

- Porte-bornes brûleur

XP

- Fiche pour le contrôle d'étanchéité

PG

- Pressostat gaz seuil minimum

PS

- Bouton de déblocage

S

- Signalisation blocage brûleur à distance

S1

- Signalisation blocage contrôle d'étan-

chéité à distance

TR

- Télécommande de réglage:

commande 1ère et 2ème allure de fonc-

tionnement.

Si l’on désire un brûleur à fonctionne-

ment à une seule allure, remplacer TR

par un pontet.

TL

- Télécommande de limite:

arrête le brûleur quand la température ou

la pression dans la chaudière a atteint la

valeur fixée.

TS

- Télécommande de sécurité:

intervient quand le TL tombe en panne

VPS - Dispositif de contrôle d'étanchéité

VR

- Vanne de réglage

VS

- Vanne de sécurité

Remarque

Les télécommandes TR et TL ne sont pas

nécessaires quand le RWF40, pour fonctionne-

ment modulant, est branché: leur fonction est

assurée par le RWF40 proprement dit.

Summary of Contents for 3897402

Page 2: ......