Installing Options

70

4

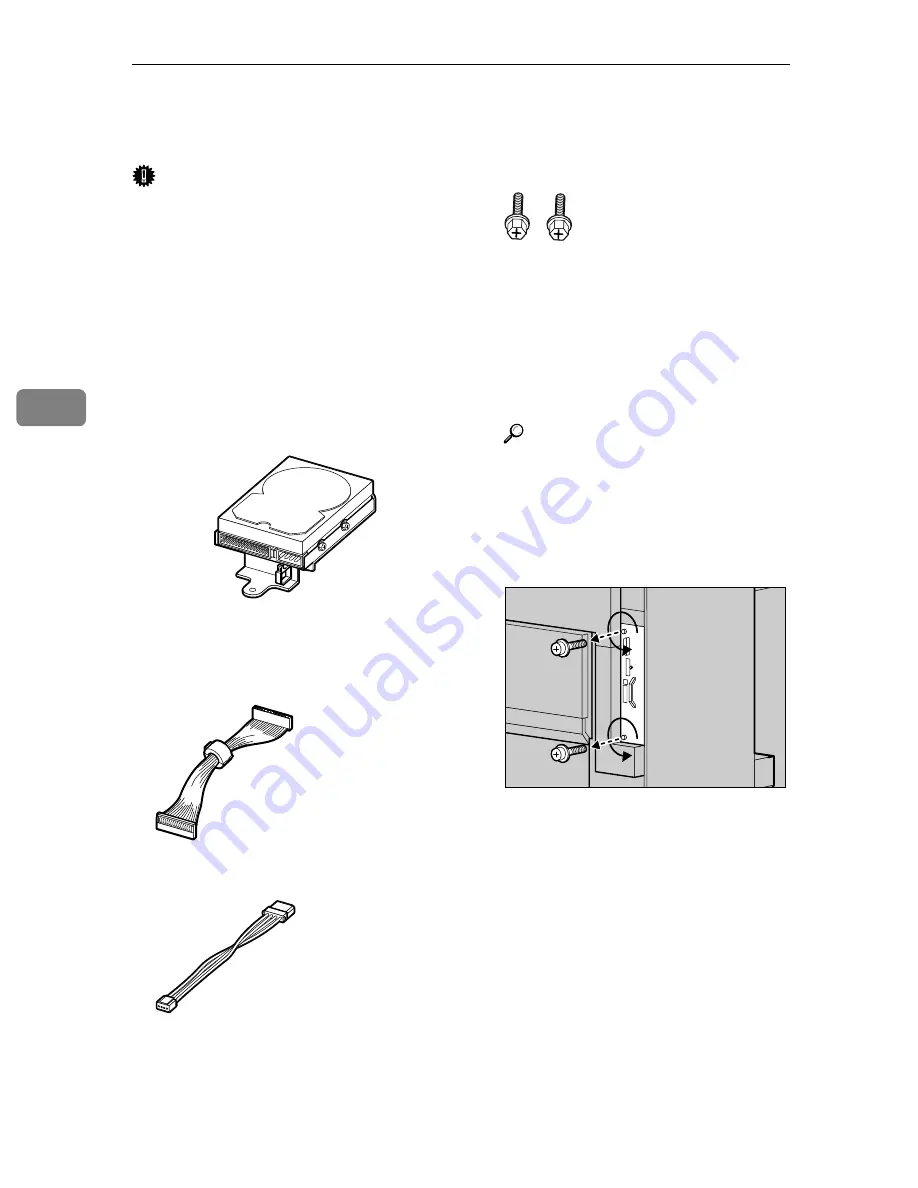

Printer Hard Disk Type 7000

Important

❒

Before handling the printer hard

disk, ground yourself by touching

something metal to discharge any

static electricity. Static electricity

can damage the printer hard disk.

❒

Do not subject the printer hard

disk to physical shocks.

AAAA

Check the contents of the box.

❖

❖

❖

❖

Printer Hard Disk Type 7000

❖

❖

❖

❖

Flat Cable

❖

❖

❖

❖

Power Cable

❖

❖

❖

❖

Two Screws

BBBB

Turn off the power, and then un-

plug the power cable.

CCCC

Slowly open the front cover of the

printer, and remove the green

screwdriver, and then close the

cover.

Reference

p.37 “Using the Screwdriver”

DDDD

Remove the two screws fastening

the controller board to the back of

the printer, using the provided

screwdriver.

The removed screws will be used

later to fasten the controller board.

ZHXP291J

ZDJP025J

Summary of Contents for CL7000 - Aficio D Color Laser Printer

Page 12: ...x ...

Page 18: ...Guide to Printer Parts 6 1 ...

Page 36: ...Setting Up 24 2 ...

Page 44: ...Preparing to Print 32 3 ...

Page 106: ...EN USA G080 6900 ...