G1128611A_1.10

Copyright ©

2004, 2005

5

Paper and Other Media

Paper and Other Media Supported by This

Printer

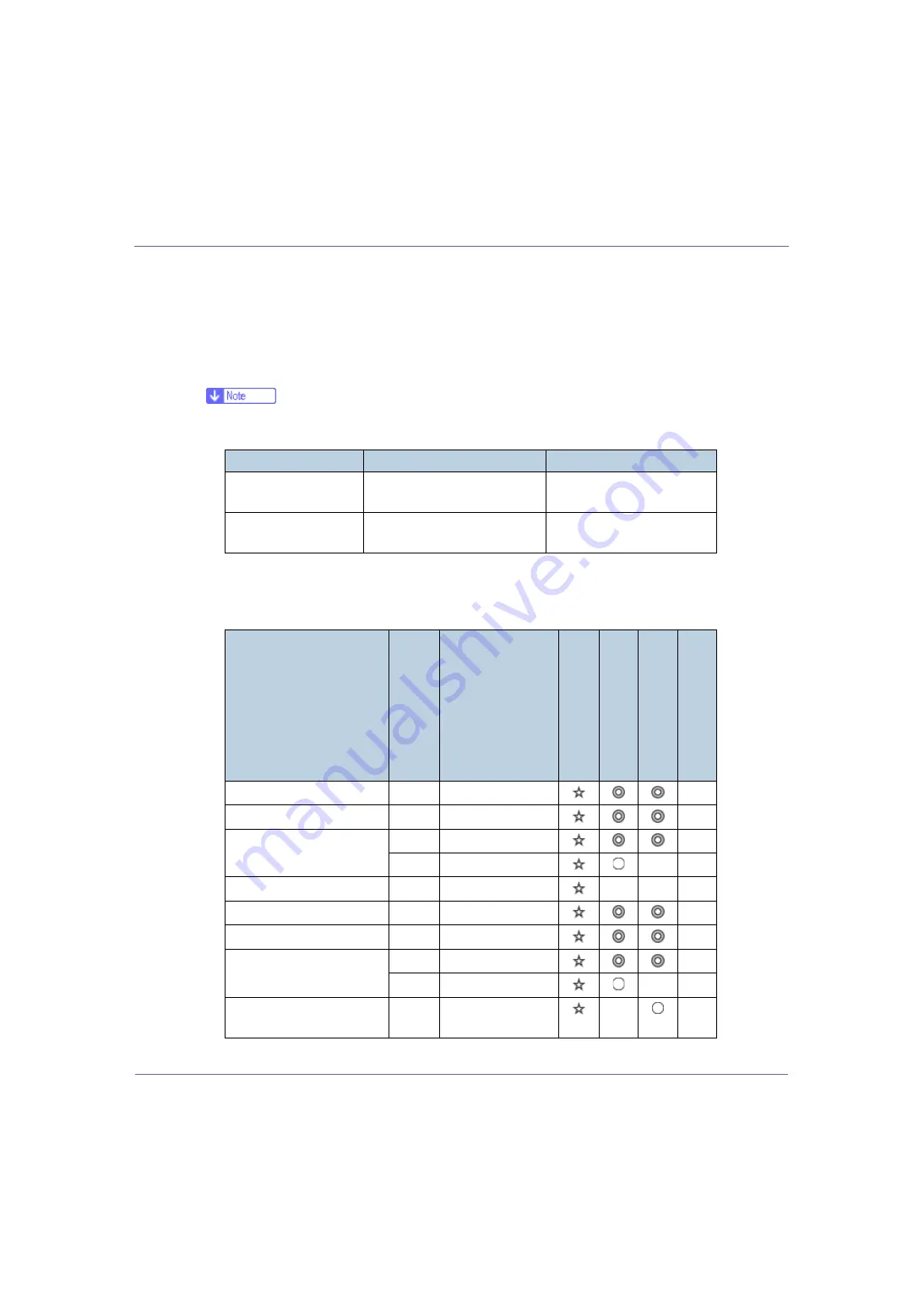

This section describes the paper size, feed direction, and the maximum amount

of paper that can be loaded into each paper tray in this printer.

❒

The following symbols and terminology are used to represent the feed direc-

tion.

❒

Be careful of the paper feed direction. The direction is determined for each pa-

per size.

❖

Input Paper Sizes (Metric version)

In this manual

On the display

Paper feed direction

K

↑

(Feed direction)

A4 (297 x 210)

8 1/2 x 11

Short-edge feed direction

L

↑

(Feed direction)

A5 (210 x 148)

8 1/2 x 5 1/2

Long-edge feed direction

Feed direction

Size (mm)

Bypass

Tray

Paper Tray (Tray1)

Paper Fe

ed Unit (Tray2/3)

Envelope Feeder Unit

A4

K

210

×

297

×

B5 JIS

K

182

×

257

×

A5

K

148

×

210

×

L

210

×

148

×

×

A6

K

105

×

148

×

×

×

Legal (LG, 8

1

/

2

×

14)

K

216

×

356

×

Letter (LT, 8

1

/

2

×

11)

K

216

×

279

×

5

1

/

2

×

8

1

/

2

K

140

×

216

×

L

216

×

140

×

×

Executive (Exec., 7

1

/

4

×

10

1

/

2

)

K

184

×

276

×

×