420 Plus Installation Manual - Print Formatting

39

6.0

Print Formatting

The

420 Plus

provides three print formats, GFMT,

NFMT, and CFMT that determine the format of the

printed output when the

key is pressed or when

a KPRINT EDP command is received. If a tare has

been entered or acquired, NFMT is used; otherwise,

GFMT is used.

Each print format can be customized to include up to

300 characters of information, such as company name

and address, on printed tickets. You can use the

i n d i c a t o r f r o n t p a n e l ( PF O R M T m e n u ) , E D P

commands, or the

Revolution

®

configuration utility to

customize the print formats.

Display will only show capital letters, press

the down arrow to view the ASCII character

decimal value on the second menu level.

Refer to Table 7-4 on page 45 and Table 7-5

on page 46 to view the ASCII character

charts.

6.1

Print Formatting Commands

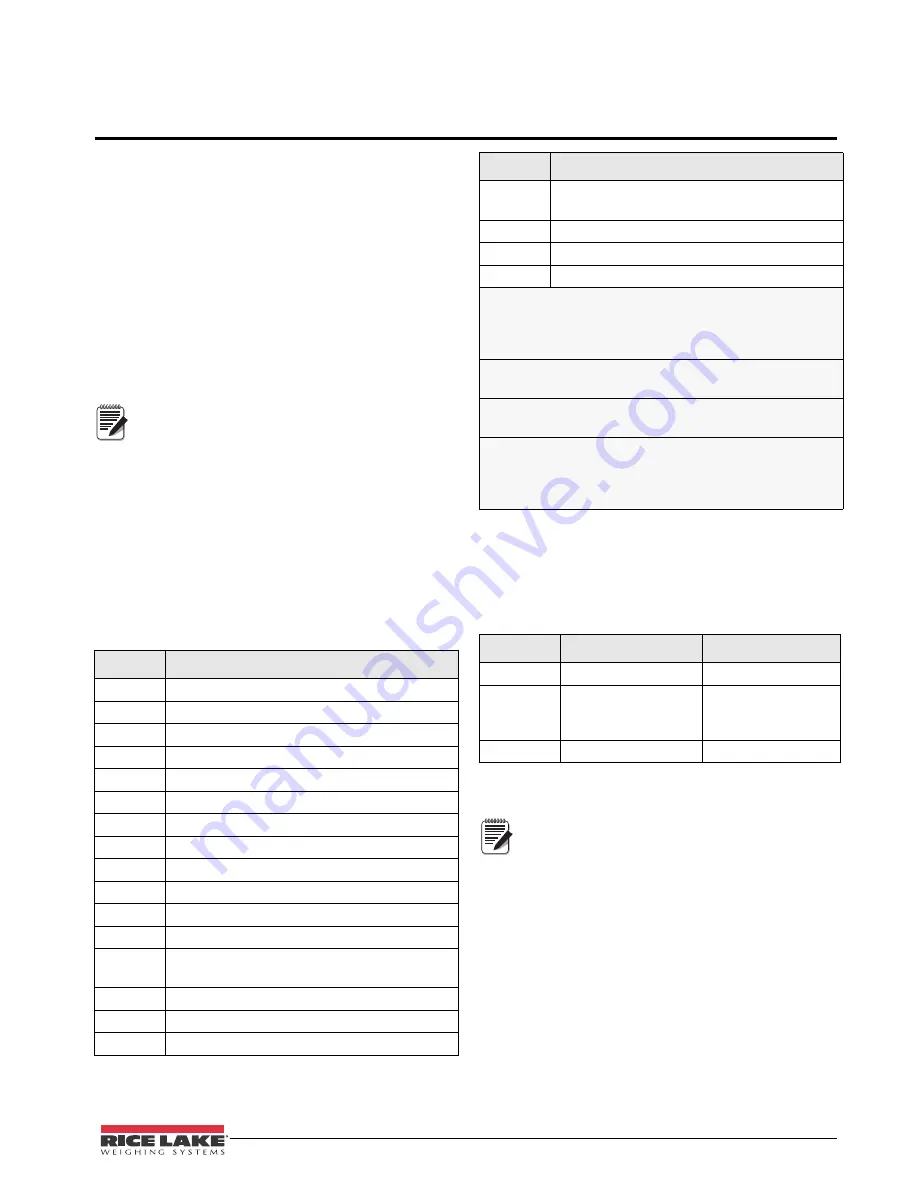

Table 6-1 lists commands you can use to format the

gross, net and count print formats. Commands

included in the format strings must be enclosed

between < and > delimiters. Any characters outside of

the delimiters are printed as text on the ticket. Text

characters can include any ASCII character that can

be printed by the output device.

The default GFMT, NFMT and CFMT print formats

use only the new line (<NL>) command and the

commands for gross, net, and tare weights in

displayed units (<G>, <N>, and <T>). The default

420

Plus

print formats are shown in Table 6-2:

The <G2>, <N2>, and <T2> commands listed

in Table 6-1 print the gross, net, and tare

weights in non-displayed units—that is, in

the units not currently displayed on the

indicator.

ID numbers included in the print format string (<UID>

command) must be set using the UID EDP command.

The 300-character limit of each print format string

includes the output field length of the print formatting

commands, not the command length. For example, if the

indicator is configured to show a decimal point, the <G>

command generates an output field of 13 characters: the

10-character weight value (including decimal point), one

space, and a two-digit units identifier.

PT (preset tare) is added to the tare weight if tare was

keyed in.

Command

Description

<G>

Gross weight in displayed units

<G2>

Gross weight in non-displayed units

<N>

Net weight in displayed units

<N2>

Net weight in non-displayed units

<T>

Tare weight in displayed units

<T2>

Tare weight in non-displayed units

<A>

Accumulated weight in displayed units

<AC>

Number of accumulator events (5-digit counter)

<AD>

Date of last accumulator event

<AT>

Time of last accumulator event

<UID>

Unit ID number

<CN>

Consecutive number

<NL

nn>

New line (

nn

= number of termination (<CR/LF>

or <CR>) characters)*

<C>

Current piece count

<W>

Current piece weight

<SP

nn>

Space (

nn

= number of spaces)*

Table 6-1. Print Format Commands

Note

<SU>

Toggle weight data format (formatted/

unformatted)**

<TI>

Time

<DA>

Date

<TD>

Time & Date

Gross, net, and tare weights are 9 digits in length, including

sign (10 digits with decimal point), followed by a space and a

two-digit units identifier. Total field length with units identifier

is 12 (or 13) characters.

ID and consecutive number (CN) fields are 1–6 characters in

length, as required.

* If

nn

is not specified, 1 is assumed. Value must be in the

range 1–99.

** After receiving an SU command, the indicator sends

unformatted data until the next SU command is received.

Unformatted data omits decimal points, leading and trailing

characters.

Format

Default Format String

Sample Output

GFMT

<G> GROSS<NL>

2046.81 lb GROSS

NFMT

<G> GROSS<NL>

<T> TARE<NL>

<N> NET<NL>

4053.1 lb GROSS

15.6 lb TARE

4037.5 lb NET

CFMT

<C><NL>

512 PC

Table 6-2. GFMT and NFMT Formats

Command

Description

Table 6-1. Print Format Commands

Note