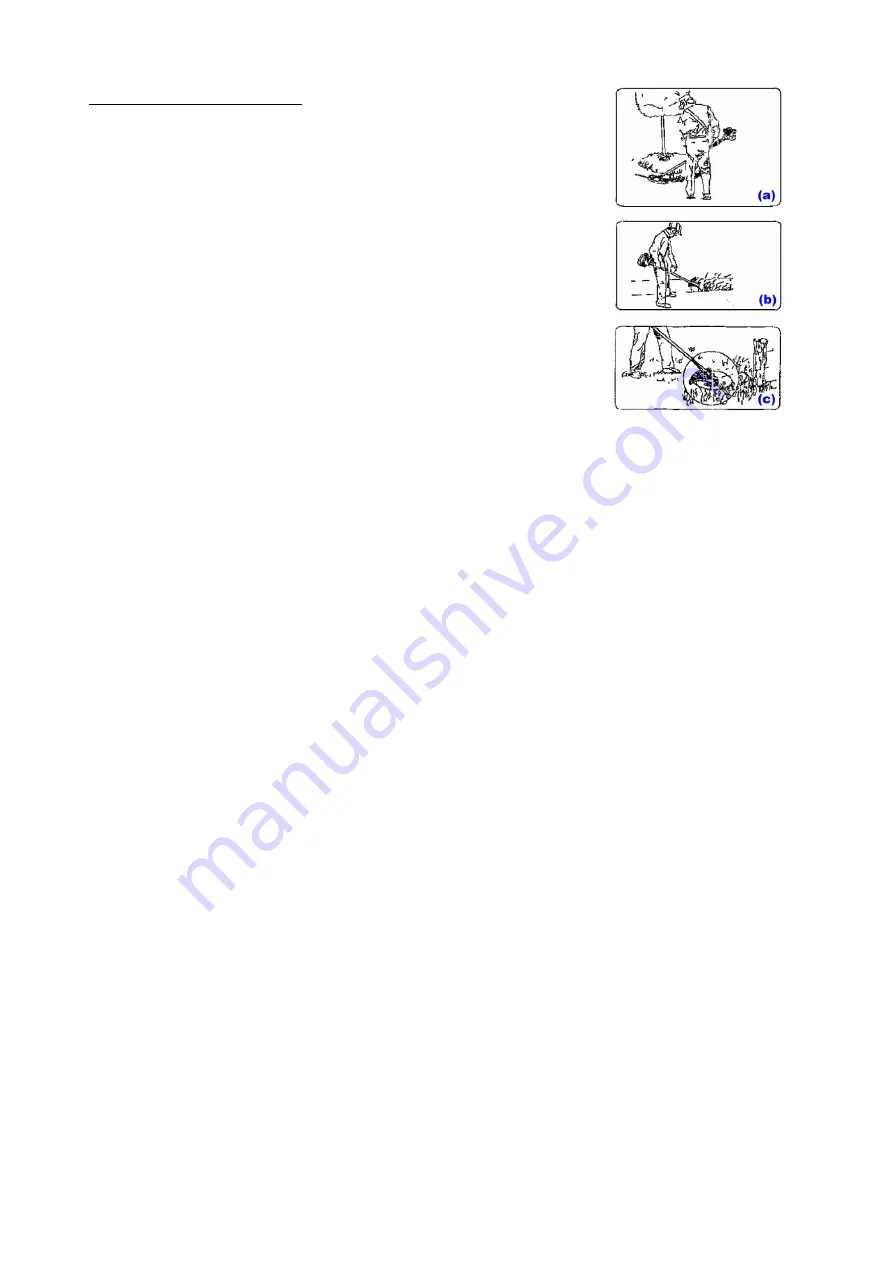

SCALPING AND EDGING

Both of these are done with the line head tilted at a steep angle.

Scalping (Fig.15 (a)) is removing top growth, including roots,

leaving the earth bare.

Edging (Fig.15 (b)) is trimming the grass back where it has spread

over a sidewalk or drive way.

During both edging and scalping, hold the unit a steep angle and in

a position where the debris and any dislodged dirt and stones, will

not come back towards you even if it ricochets off any hard

surface.

Although the figures show examples of how to edge and scalp,

every operator must find for himself the angles which suits his

body size and cutting situation.

WARNING

! Do not to use a steel blade for edging or scalping

Do not trim in any area where there are strands of

fencing wire.

Do not cut where you cannot see what the cutting

device is cutting.

Fig.15

(

a) Scalping

(b) Edging

(c) Beware of obstacles

(avoid wires)

5.2.2- Cutting with a metal blade

The 3-tooth metal blade provided with the machine is intended for cutting brushes and weeds.

Do NOT use saw blade with this machine.

WARNING!

1. Do not use a brush cutter for cutting trees

2. Do not cut with dull, cracked or damaged metal blade.

3. Before cutting, inspect working area for obstructions (such as boulders, metal

stakes or strands of wire from broken fences) and remove them. If an obstruction

cannot be removed, mark its location so that you can avoid it with the blade.

Rocks and metal will dull or damage the blade.

Wires can catch on the blade head and flap around or be thrown into the air.

4. Use the shoulder harness at all times! Harness the unit on the right side of your

body. Adjust the harness so that the unit hangs a few inches above ground level.

SCYTHING WEEDS

:

This is cutting by swinging the blade in a level arc.

This method quickly allows to clear areas of field grass and weeds.

Scything should not be used to cut large, tough weeds or woody growths.

Scything can be done in both directions (warning! Debris may be thrown towards user’s

direction), or just in one direction (which results in the debris being thrown away from user).

For that, use the side of the blade that is rotating away from you and tilt down the blade slightly on

this same side.

If kickback occurs, the blade may be dull, or the material so thick and hard that you should use

other tool instead of this machine.

Do not force the blade to cut.

Do not change the angle of cut during operation.

Avoid using any pressure or leverage which could cause the blade to bind or crack.

VI. MAINTENANCE AND STORAGE

Page

46

/

49