SECTION II: INSTALLATION AND MAINTENANCE

32

IMPORTANT!

Mixing the water with glycol modifies the

performance of the unit.

The table below gives the proportions of ethylene glycol which are

required to give frost protection in a range of conditions Maximum

ethylene glycol content 30%.

Projected air temperature in °C

2

0

-3

-6

-10

% glycol in weight

10 15 20 25 30

Freezing temperature in °C

-5

-7

-10 -13 -16

To set the antifreeze set point, see

Par. I.8.7

.

II.7 ELECTRICAL

CONNECTIONS

DANGER!

Always install a general automatic switch in a

protected area near the appliance with a

characteristic delayed curve, sufficient capacity and

breaking power. There should be a minimum

distance of 3 mm between the contacts.

Earth connection is compulsory by law and

safeguards the user while the machine is in use.

DANGER!

Electrical connection of the unit must be carried out

by personnel skilled in the matter and in

compliance with the regulations in effect in the

country where the unit is installed. Non-conforming

electrical connection relieves

RHOSS

S.p.a. from

all responsibility for damage to persons and

property.

In making the electrical connections to the board,

cables must be routed so that they do not touch the

hot parts of the machine (compressor, flow pipe

and liquid line). Use the slots provided in the panel

in the compressor compartment to anchor cable

ties and protect the cables from possible burrs.

IMPORTANT!

For electrical connections of the unit and the

accessories, follow the wiring diagrams which are

supplied with them.

The safety door interlock automatically prevents electric power being

fed to the unit if the cover panel over the electrical panel is opened.

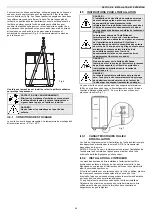

After removing the right-hand lower side panel of the unit, run the power

supply cables through the cable clamps provided on the outside of the

right-hand part of the bodywork, and through the cable clamps at the

base of the electrical panel, being careful to avoid the hot parts inside

the machine.

Electrical connections must be made in compliance with the regulations

in force and following the wiring diagrams supplied with the unit.

The power supply, provided by the three-phase line and the neutral line,

must be carried to the main isolator switch.

The supply cable must be of the flexible type, with PVC sheathing of no

lighter than H05RN-F: for the section, refer to the table below or the

wiring diagram.

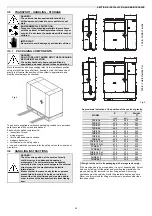

Model

114

117

121

126

Section L1-L2-L3

mm²

4 4 6 6

PE section

mm²

4

4

6

6

The earth conductor must be longer than the other conductors in order

to ensure that in the event of the cable clamping device becoming

slack, it will be the last to come under strain.

IMPORTANT!

If a pump is fitted in a unit without a storage tank, it

must be controlled by a contactor connected to

terminals J6 on the electronic board inside the

electrical panel.

The maximum load which can be applied is 230V/5A

(AC1).

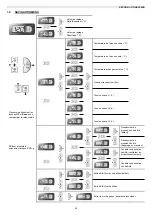

II.7.1.1 Remote

management using connections set

up by the installer

The connection between board and switch or remote light must be

made with screened cable consisting of 2 twisted 0,5 mm2 wires and

the screening. The screening must be connected to the earth screw on

the panel (on one side only). The maximum permitted distance is 30 m.

SCR

- Remote ON/OFF control selector.

SEI

- Summer/winter selector.

LBG

- General lockout light.

•

Remote ON/OFF enablement (SCR)

IMPORTANT!

When the unit is switched OFF using the remote

control selector, the letters Scr appear on the on

board control panel display.

Remove the

ID8

terminal bridge on the electronic board and connect

the wires coming from the remote control ON/OFF selector (selector to

be installed by the installer).

Open contact:

the unit is OFF.

ATTENTION

Closed contact:

the unit is ON.

•

Remote summer/winter enablement on THCE

Connect the wires coming from the remote summer/winter selector on

the

ID7

terminal present on the electronic board.

At this point, alter parameter

SUr

from

n

to

y

(see

par.

I.9

).

Open contact:

heating cycle.

ATTENTION

Closed contact:

cooling cycle.

•

LBG remote control

In the event of remote controlled signals, connect the lamp following the

indications in the wiring diagram supplied with the machine (max 24

Vac).

II.7.1.2 Remote management using accessories

supplied separately

It is possible to remotely control the entire machine by linking a second

keyboard to the one built into the machine (KTR accessory).

To select the remote control system, consult paragraph

II.2

. The use

and installation of the remote control systems are described in the

Instruction Sheets

provided with the same.

II.8 START-UP

INSTRUCTIONS

IMPORTANT!

Machine commissioning or the first start up (where

provided for) must be carried out by skilled

personnel from workshops authorised by

RHOSS

S.p.A., qualified to work on this type of product.

DANGER!

Before starting up, make sure that the installation

and electrical connections conform with the

instructions in the wiring diagram. Also make sure

that there are no unauthorised persons in the

vicinity of the machine during the above operations.

IMPORTANT!

The use and maintenance manual for the safety

valve, fans and pumps is enclosed with this manual

and must be read in all its parts.

DANGER!

At any time when the gas charge is being topped

up, do NOT approach the preset blowoff levels of

the bleed valves. When they are set off, there is a

loud and violent outburst of gas and oil. The bleed

valve drain is not channelled!

The liquid receivers are equipped with bleed valves calibrated at 32 bar.

Summary of Contents for MICROSYSTEM TCCE 114 H Series

Page 109: ...NOTE 109 NOTE...

Page 110: ...NOTE 110 NOTE...

Page 111: ...Codice Variante Data emissione Modifica H50804 09 11 05 Nuova edizione...