SDM – Slurry Density Meter

13

www.rhosonics.com

INSTALLATION

2.3.4

Instructions

1.

Carefully align the pipe sections with the spool in order to avoid stress at the flange surface of the

spool. In addition, the piping must be secured and supported to prevent movement which can

create excess stress and flange face damage.

2.

Once the gasket is in place, align the bolt holes of the spool and the adjacent flange faces

3.

Lightly lubricate and insert all bolts and washers and loosely apply the nuts

4.

Number all bolts for record purposes

5.

Make sure the faces of the mating surfaces are flush against gasket prior to bolting down the

flanges.

6.

Tighten the nuts by hand until they are snug. Establish uniform pressure over the flange faces by

tightening the bolts in increments up described as below.

2.3.5

4 and 8 Bolt Flanges

First round - 30% of final torque (flange sequential order, crisscross)

Second round- 60% of final torque (flange sequential order, crisscross)

Third round - 100% of final torque (flange sequential order, crisscross)

One final time after 24 hours - clockwise or counter clockwise sequentially around the flange

2.3.6

12 Bolt Flanges and More

First round - 20% of final torque (flange sequential order, crisscross)

Second round - 40% of final torque (flange sequential order, crisscross)

Third round - 80% of final torque (flange sequential order, crisscross)

Fourth round - 100% of final torque (flange sequential order, crisscross)

One final time after 24 hours - clockwise or counter clockwise sequentially around the flange.

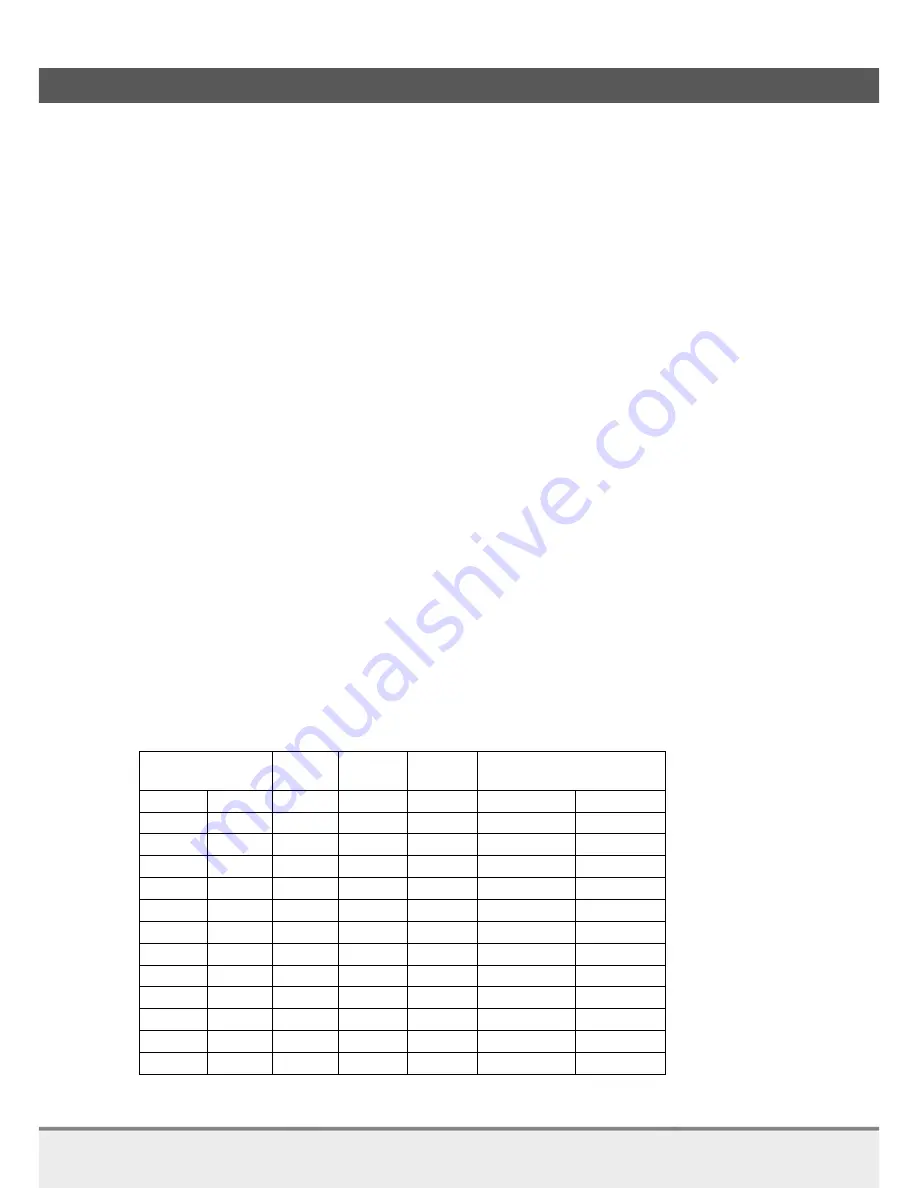

In below table, torque values are given for Rhosonics metal spools (SDM-1) and metal wafers (SDM-4 or

SDM-5). These values assume the flanged joint connects the spool to a CLASS 150 flange. These values are

for Spiral Wound Gaskets, ASME B16.5.

Nom. OD

Bolt

hole

No.Bolts Size Bolts Preferred Torque per Bolt

(Inch)

(mm)

(mm)

M…

(ft lb)

(Nm)

3

80

19

4

16

120

163

4

100

19

8

16

120

163

5

125

22.2

8

18

200

271

6

150

22.2

8

18

200

271

8

200

22.2

8

18

200

271

10

250

25.4

12

22

320

434

12

300

25.4

12

22

320

434

14

350

28.6

12

24

490

664

16

400

28.6

16

24

490

664

18

450

31.7

16

27

710

963

20

500

31.7

20

27

710

963

24

600

34.9

20

30

1000

1356