F3788-7-04

Maintenance Section 5-10

MAINTENANCE

MAINTENANCE

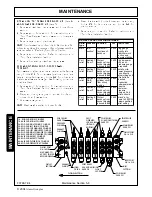

USE THE FOLLOWING TORQUES WHEN SPECIAL TORQUES ARE NOT GIVEN

GENERAL TORQUE SPECIFICATIONS

AMERICAN STANDARD CAP SCREWS

METRIC CAP SCREWS

SAE

Grade

5

8

Metric Class

8.8

10.9

Cap

Screw

TORQUE

TORQUE

Cap Screw

TORQUE

TORQUE

Size

FT-LBS

Nm

FT-LBS

Nm

Size

FT-LBS

Nm

FT-LBS

Nm

Inches

MIN

MAX

MIN

MAX

MIN

MAX

MIN

MAX

Millimeters

MIN

MAX

MIN

MAX

MIN

MAX

MIN

MAX

1/4-20

6.25

7.25

8.5

10

8.25

9.5

11

13

M6x100

6

8

8

11

9

11

12

15

1/4-28

8

9

11

12

10.5

12

14

16

M8 x 1.25

16

20

215

27

23

27

31

36.5

5/16 - 18

14

15

19

20

18.5

20

25

27

M10 x 1.50

29

35

39

47

42

52

57

70

5/16 - 24

17.5

19

23

26

23

25

31

34

M12 x 1.75

52

62

70

84

75

91

102

123

3/8 - 16

26

28

35

38

35

37

47.5

50

M14 x 2.00

85

103

115

139

120

146

163

198

3/8 - 24

31

34

42

46

41

45

55.5

61

M16 x 2.50

130

158

176

214

176

216

238

293

7/16 - 14

41

45

555

61

55

60

74.5

81

M18 x 2.50

172

210

233

284

240

294

325

398

7/16 - 20

51

55

69

745

68

75

92

102

M20 x 2.50

247

301

335

408

343

426

465

577

½ - 13

65

72

88

975

86

96

116

130

M22 x 2.50

332

404

450

547

472

576

639

780

½ - 20

76

84

103

114

102

112

138

152

MM24 x 3.00

423

517

573

700

599

732

812

992

9/16 - 12

95

105

129

142

127

140

172

190

M27 x 3.00

637

779

863

1055

898

1098

1217

1488

9/16 - 18

111

123

150

167

148

164

200

222

M30 x 3.00

872

1066

1181

1444

1224

1496

1658

2027

5/8 - 11

126

139

171

188

168

185

228

251

NOTE: These values apply to fasteners as

received from the supplier, dry or when lubricated

with normal engine oil. They do not apply if

special graphite or molydisulphide greases or

other extreme pressure lubricants are used.

5/8 - 18

152

168

206

228

203

224

275

304

¾ - 10

238

262

322

355

318

350

431

474

¾ - 16

274

305

371

409

365

402

495

544

7/8 - 9

350

386

474

523

466

515

631

698

7/8 -14

407

448

551

607

543

597

736

809

1 - 8

537

592

728

802

716

790

970

1070

1 - 14

670

740

908

1003

894

987

1211 1337

Assembly Torque

Size

Thread

Size

in. lb.

ft. lb.

Tube

Connection

F.F.F.T.

Swivel Nut

or Hose

Connection

F.F.F.T.

-4

7/16-20

140 ± 10

12 ± 1

2

2

-5

1/2-20

180 ± 15

15 ± 1

2

2

-6

9/16-18

250 ± 15

21 ± 1

1 1/2

1 1/4

-8

3/4-16

550 ± 25

45 ± 5

1 1/2

1

-12

1 1/16-12

1000 ± 50

85 ± 5

1 1/4

1

-16

1 5/16-12

1450 ± 50

120 ± 5

1

1

-20

1 5/8-12

2000 ± 100

170 ± 10

1

1

-24

1 7/8-12

2400 ± 150

200 ± 15

1

1

-32

2 1/2-12

3200 ± 200

270 ± 20

1

1

Torque Specifications for

37º JIC Fittings

Assembly Torque

Size

Thread

Size

in. lb.

ft. lb.

F.F.F.T.

2

5/16-24

90 ± 5

7.5 ± 0.5

1 ± .25

3

3/8-24

170 ± 10

14 ± 1

1 ± .25

4

7/16-20

220 ± 15

18 ± 1

1 ± .25

5

1/2-20

260 ± 15

22 ± 1

1 ± .25

6

9/16-18

320 ± 20

27 ± 2

1.5 ± .25

8

3/4-16

570 ± 25

48 ± 2

1.5 ± .25

10

7/8-14

1060 ± 50

90 ± 5

1.5 ± .25

12

1 1/16-12

1300 ± 50

110 ± 5

1.5 ± .25

14

1 3/16-12

1750 ± 75

145 ± 6

1.5 ± .25

16

1 5/16-12

1920 ± 25

160 ± 6

1.5 ± .25

20

1 5/8-12

2700 ± 150

225 ± 12

1.5 ± .25

24

1 7/8-12

3000 ± 150

250 ± 12

1.5 ± .25

32

2 1/2-12

3900 ± 200

325 ± 15

1.5 ± .25

Torque Specifications for

SAE O-Ring Fittings

Summary of Contents for 95HD

Page 4: ...Safety Section 1 1 SAFETY SECTION 2004 Alamo Group Inc...

Page 11: ...F3788 7 04 Safety Section 1 8 SAFETY SAFETY 2004 Alamo Group Inc...

Page 16: ...INTRODUCTION SECTION Introduction Section 2 1 2004 Alamo Group Inc...

Page 20: ...Assembly Section 3 1 ASSEMBLY SECTION 2004 Alamo Group Inc...

Page 24: ...Operation Section 4 1 OPERATION SECTION 2004 Alamo Group Inc...

Page 29: ...MAINTENANCE SECTION Maintenance Section 5 1 2004 Alamo Group Inc...

Page 37: ...MAINTENANCE MAINTENANCE F3788 7 04 Maintenance Section 5 9 2004 Alamo Group Inc...