INSTALLING SC SPOOL POSITIONER KIT (Item 2)

AND FLOAT POSITIONER KIT (Item 5)

1. Remove socket head cap screws and bonnet from

section.

2. Remove spool from section. Follow instructions in

Spool Seal Removal section except do not remove

seals.

3. Replace parts in spool positioner kit.

NOTE: Spool screw on end of spool is loctited in place. Do

not replace unless it is damaged. If spool screw must be

replaced, refer to Replacing Spool Ends Section.

4. Replace spool in section. Refer to instructions in

Spool Seal Installation section.

5. Replace bonnet and socket head cap screws.

REPLACING SPOOL ENDS - CENTER TWO

SECTIONS

Spool extensions (handle end) are installed at the factory

using Loctite 262. Spool screws (positioner end) are

installed at the factory using Loctite 242. Do not replace

them unless they are damaged. Use following procedure

to replace them.

1. Remove spool from section. Follow instructions in

Spool Seal Removal Section except do not remove

seals.

2. Clamp spool using vice grips on land section of spool

not machined for valve bore.

3. Unscrew damaged end.

NOTE: Heat may be applied to loosen Loctite.

4. Clean threads with Loctite Primer and install using

Loctite 262 for handle ends and Loctite 242 for

positioner ends.

5. Replace spool in section. Refer to instructions in

Spool Seal Installation section.

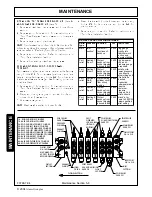

MAINTENANCE

MAINTENANCE

F3788-7-04

Maintenance Section 5-8

OUTLET PORT

3/4-16 O.R.

MACHINED TO

ACCEPT POWER

BEYOND SLEEVE

OUTLET

SECTION

PORT RELIEF

2650 PSI

PRESSURE

O-RINGS

EXHAUST

O-RING

LOAD

CHECK

EXHAUST

O-RING

6B: ROD END DIPPERSTICK CYLINDER

6A: BASE END DIPPERSTICK CYLINDER

5B: ROD END BUCKET CYLINDER

5A: BASE END BUCKET CYLINDER

4B: BASE END RIGHT STABILIZER CYLINDER

4A: ROD END RIGHT STABILIZER CYLINDER

3B: BASE END LEFT STABILIZER CYLINDER

3A: ROD END LEFT STABILIZER CYLINDER

2B: ROD END LEFT SWING CYLINDER

2A: ROD END RIGHT SWING CYLINDER

1B: BASE END BOOM CYLINDER

1A: ROD END BOOM CYLINDER

FLOW DIRECTION

PORT RELIEF

W/ ANTI CAVITATION

2650 PSI

PILOT

OPERATED

LOCK VALVES

(TOP AND

BOTTOM)

PORT RELIEF

W/ ANTI CAVITATION

2650 PSI

FLOAT

SECTION

PORT RELIEF

3500 PSI

PORT RELIEF

2650 PSI

MAIN RELIEF

2500 PSI

OUTLET PORT

3/4-16 O.R.

INLET PORT

3/4-16 O.R.

INLET

SECTION

1A

6B

6A

5B

5A

4B

4A

3B

3A

2B

2A

1B

RELIEF VALVE CARTRIDGE TABLE

Relief

type

Location Function

PSI How to test

Main

Port

relief

Port

relief

Port

relief

Port

relief

2500

3500

2650

2650

2650

Inlet

section*

Section 1,

A port*

Section 1,

B port*

Section 2,

A & B

ports*

Section 5,

A port*

Protect all

functions of

backhoe

Protect

backhoe from

bucket digging

induced loads

Plug gauge

directly into

stabilizer work

section and

operate stabilizer

A porta-power

with an oil

pressure guage

is required.

Install porta-

power pressure

hose directly

into working port

of relief to be

checked.

Pressurize

porta-power and

observe

maximum

pressure

attained. Port

reliefs should

“crack” at or

down to 200 PSI

below specified

relief setting.

Protect

backhoe from

bucket digging

induced loads

Protect swing

cylinder circuit

from shock

loading

Protect

backhoe from

bucket digging

induced loads

Port

relief

2650

Section 6,

A port*

Protect

backhoe from

bucket digging

induced loads

© 2004

Alamo Group Inc.

Summary of Contents for 95HD

Page 4: ...Safety Section 1 1 SAFETY SECTION 2004 Alamo Group Inc...

Page 11: ...F3788 7 04 Safety Section 1 8 SAFETY SAFETY 2004 Alamo Group Inc...

Page 16: ...INTRODUCTION SECTION Introduction Section 2 1 2004 Alamo Group Inc...

Page 20: ...Assembly Section 3 1 ASSEMBLY SECTION 2004 Alamo Group Inc...

Page 24: ...Operation Section 4 1 OPERATION SECTION 2004 Alamo Group Inc...

Page 29: ...MAINTENANCE SECTION Maintenance Section 5 1 2004 Alamo Group Inc...

Page 37: ...MAINTENANCE MAINTENANCE F3788 7 04 Maintenance Section 5 9 2004 Alamo Group Inc...