VALVE SERVICE

REPLACING SECTIONS

For clarification, the inlet cover [cover containing main

relief cartridge (18) ] will be called the left end of the valve

assembly.

Reassemble valve on a flat surface to insure proper

section alignment.

1. Remove handle assembly from section being

removed.

2. Remove valve from backhoe.

3. Thoroughly clean valve assembly.

4. Before disassembly, mark each section numerically to

avoid incorrect reassemble.

5. Remove four hex nuts and lock washers from right

(outlet cover) end of valve.

6. Slide outlet cover and each section off tie rods.

7. Replace sections as needed. Reassemble valve.

NOTE: Refer to Replacing Section Seals if seals need to

be replaced.

WARNING: Do not prelube O-ring section

seals prior to installation. Compression of

lubricants can distort valve causing spool

binding.

8. Torque stud nuts evenly to 15ft. Lbs .

CAUTION: If stud nuts are not tightened to

proper torque, valve spools may bind or stick,

or cause O-ring seals to extrude.

9. Reinstall handle assembly. Use locite 242 (blue) on all

screws.

REPLACING SECTION SEALS

1. Disassemble valve as described in previous section.

2. Remove old O-ring section seals. Be careful not to

scratch or otherwise damage sealing surface areas.

3. Thoroughly clean O-ring counter bores and surfaces of

each valve section.

4. Place valve assembly on a flat surface for reassembly.

5. Replace four O-ring seals. Seal Kit contains the

number of section seals required for one work

section/inlet cover.

6. Replace work sections on assembly studs in reverse

order in which they were removed. O-ring counter

bores (with O-rings in place) should be to your right

(downstream side of section) with inlet cover on your

left.

NOTE: Use care when sliding work sections on tie rods

to avoid dislodging O-rings.

7. When all work sections and outlet cover are positioned

on the assembly studs, replace lock washers and nuts.

8. Support alve on valve mounting brackets (Item 24,

p.22). Tap all sections downward with rubber mallot to

align sections evenly against rods.

8. Torque stud nuts evenly 15ft. Lbs.

SPOOL SEAL REMOVAL

1. Remove handle assembly. Center two sections -

Remove clevis pin from spool.

2. Remove bonnet and spool positioner assembly from

rear of the work section.

3. Carefully slide spool out of valve housing.

4. Remove old spool seals. Be careful not to scratch or

damage spool bore and sealing surfaces.

5. Thoroughly clean both seal grooves and exposed end

of spool.

SPOOL SEAL INSTALLATION

1. Lightly oil and insert one new spool seal in handle end

(front) seal groove of valve housing. Verify seal fit by

carefully running your finger around exposed edge of

seal. Seal should have a perfect ridge with no kinks or

twists.

2. Lightly oil valve spool and, starting from positioner end

(rear), reintroduce spool into valve housing.

3. Slowly push spool past seal with a twisting motion.

Stop when seal groove is exposed on positioner end.

CAUTION: Do not pull spool too far, as this

will allow seal in front groove to enter a spool

groove. Seal may be cut when spool is

pushed back.

4. Lightly oil and insert remaining spool seal in bonnet

end seal groove. Verify seal fit by carefully running your

finger around exposed edge of seal. Seal should have

a perfect ridge with no kinks or twists.

5. Return spool to center position with a twisting motion.

6. Reattach spool positioner. Use loctite 242 (blue) thread

locking compound on spool screw holding positioner

parts to spool. Be careful not to over torque this screw

and twist it off. Use 7ft. lb. maximum torque. Slide

bonnet in place. Replace bonnet screws. Torque

bonnet screws to 5-7 ft. Lbs.

7. Replace spool clevis pin and handle assembly.

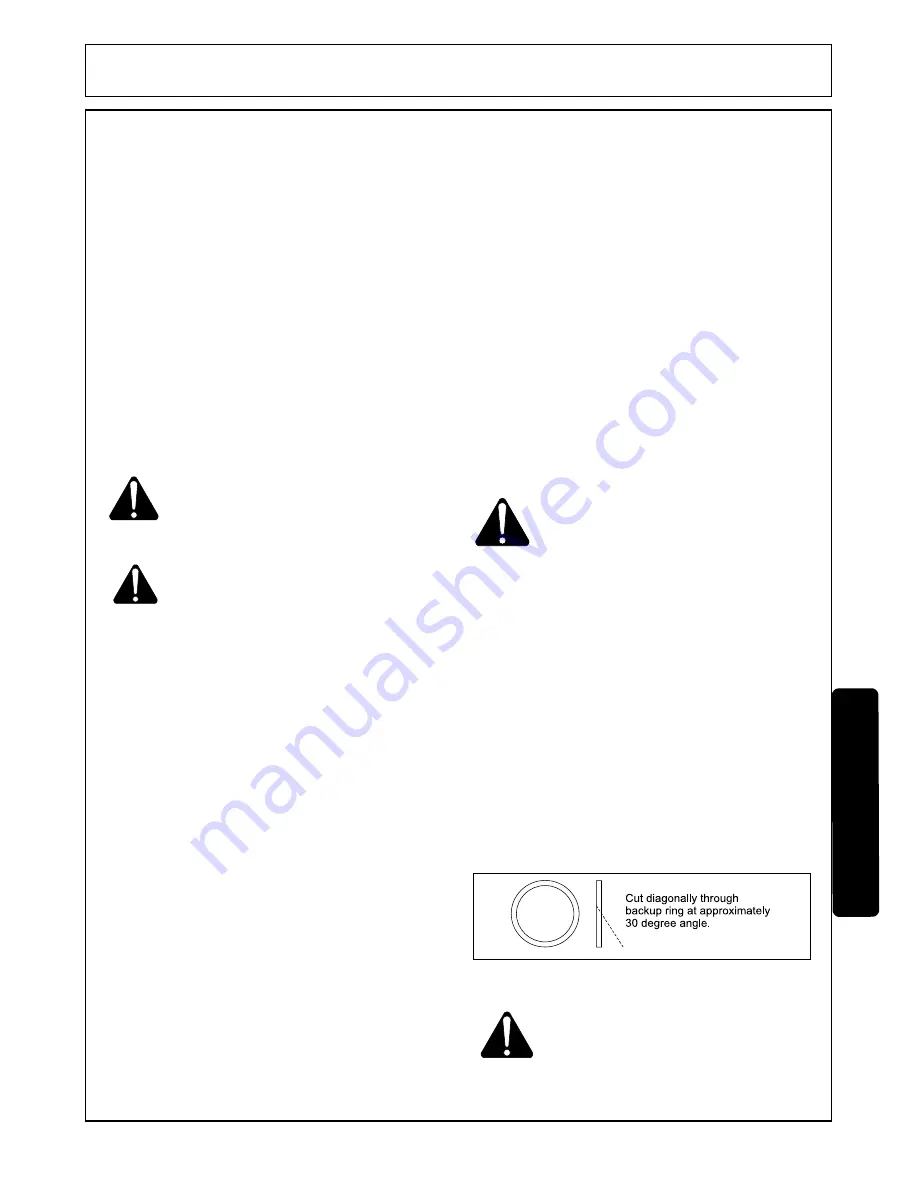

REPLACING DAMAGED BACKUP RINGS

Backup rings are installed at the factory using a special

sizing tool.

Do not replace backup rings offered in seal kits unless

original ring has been damaged.

1. If backup ring must be replaced, cut replacement

backup ring as shown.

CAUTION: Make only one diagonal cut in

backup ring. Do not cut backup ring into two

pieces.

2. Slip backup ring over cartridge and into place.

MAINTENANCE

MAINTENANCE

F3788-7-04

Maintenance Section 5-7

© 2004

Alamo Group Inc.

Summary of Contents for 95HD

Page 4: ...Safety Section 1 1 SAFETY SECTION 2004 Alamo Group Inc...

Page 11: ...F3788 7 04 Safety Section 1 8 SAFETY SAFETY 2004 Alamo Group Inc...

Page 16: ...INTRODUCTION SECTION Introduction Section 2 1 2004 Alamo Group Inc...

Page 20: ...Assembly Section 3 1 ASSEMBLY SECTION 2004 Alamo Group Inc...

Page 24: ...Operation Section 4 1 OPERATION SECTION 2004 Alamo Group Inc...

Page 29: ...MAINTENANCE SECTION Maintenance Section 5 1 2004 Alamo Group Inc...

Page 37: ...MAINTENANCE MAINTENANCE F3788 7 04 Maintenance Section 5 9 2004 Alamo Group Inc...