POSSIBLE CAUSE

CORRECTIVE ACTION

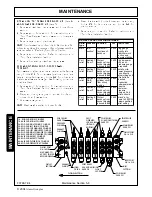

17

Oil leakage past spool

seal into spool cap.

If spool cap contains oil,

replace spool seal o-ring.

Check for restriction from

valve out port reservoir.

See Fig. 6, item 23.

18

Broken return springs. Return springs. See Fig.

6, items 2 & 5.

19

Bent spool.

Return for factory repair

or replace with new spool

section. See Fig. 6,

items 38, 39, 40.

20

Foreign particles.

Clean system and valve.

21

Misalignment of

control handle linkage.

Check linkage for binding

condition. Fig. 6, items 8,

11, 12.

22

Spool not moved to

full stroke.

Spool travel should be

265" either way or 53"

total. See Fig. 11, items

38, 39, 40.

23

Relief valve setting in

control valve too low

or defective.

Pressure should be 2500

PSI. Clean or overhaul

relief valve or replace

cartridge. See Fig. 11,

item 18.

24

Work port relief valve

in control valve stuck

open or

malfunctioning.

Clean relief or replace

cartridge. Do not disturb

pressure setting. See

Fig. 6, items 16, 17, 41.

25

Worn control valve.

Replace control valve.

26

Load check poppet in

control valve not

holding.

Clean check poppet(s)

carefully. Ensure free

movement and proper

seating or replace check

poppet(s). See Fig. 6,

item 26.

27

Damaged or worn

spool seals.

Replace spool end seals.

See Fig. 6, item 23.

28

Check ball in anti-

cavitation is stuck or

not seated properly.

Clean anti-cavitation

valve carefully. Assure

that checks move freely

and seat properly or

replace cartridge. See

Fig. 6, item 17.

29

Valve cap and center

return mechanism

binding.

Loosen screws holding

cap on valve. See Fig. 6,

items 2 & 5. Operate

valve spool and retighten

screws.

POSSIBLE CAUSE

CORRECTIVE ACTION

30

Restrictor in cylinder

ports are plugged.

Check restrictors for

debris and clean. See

Fig. 11, item 3.

31

Hoses plumbed incor-

rectly.

Check hose plumbing.

See Fig. 11.

32

Excessive hydraulic

pressure due to tractor

mechanical forces.

Do not move tractor

unless backhoe is up in

transport position and

backhoe can not contact

ground.

33

After valve has been

repaired, grease

lubrication on o-rings

between sections

cause spools to bind

due to valve distortion.

Disassemble and remove

lubricant from around o-

rings.

34

Valve studs are not

torqued to 15 ft. lbs.

Distortion causes

spool to bind or o-

rings to extrude.

Check studs for proper

torque.

This valve is a precision device and is not intended for

extensive field adjustment or repair. Field replacement

parts are limited to seal kits, cartridges, valve sections

and tie rod ends. Beyond replacement of these parts,

opening of check cavities and certain relief valve

cavities to examine for trapped dirt, or resetting main

relief valve with the use of a good pressure gauge,

valve should be returned for service.

Dirt and shreds of packing material are the usual causes

of valve malfunction. Be sure that oil supply is kept clean.

Use only factory supplied packings in cylinder repair.

Fittings and hoses must be clean before being removed.

Pages 5-7 & 5-8 explain proper valve repair procedure.

Pages 5-9, 6-16 &6-17 illustrate valve and lists repair

parts.

NOTE: Pay close attention to all caution warning notes so

valve will not have to be returned to manufacturer for

reconditioning.

Troubleshooting guide is designed to help qualified

individuals, with valve service training, correct minor

problems which may develop. If valve is under warranty

do not attempt disassembly for repairs. Contact your

authorized dealer.

MAINTENANCE

MAINTENANCE

F3788-7-04

Maintenance Section 5-6

© 2004

Alamo Group Inc.

Summary of Contents for 95HD

Page 4: ...Safety Section 1 1 SAFETY SECTION 2004 Alamo Group Inc...

Page 11: ...F3788 7 04 Safety Section 1 8 SAFETY SAFETY 2004 Alamo Group Inc...

Page 16: ...INTRODUCTION SECTION Introduction Section 2 1 2004 Alamo Group Inc...

Page 20: ...Assembly Section 3 1 ASSEMBLY SECTION 2004 Alamo Group Inc...

Page 24: ...Operation Section 4 1 OPERATION SECTION 2004 Alamo Group Inc...

Page 29: ...MAINTENANCE SECTION Maintenance Section 5 1 2004 Alamo Group Inc...

Page 37: ...MAINTENANCE MAINTENANCE F3788 7 04 Maintenance Section 5 9 2004 Alamo Group Inc...