Operative Instructions

18

drainage bottles and other human waste containers.

The device, using washing jets inside the washing

chamber, can thoroughly empty and wash the above

indicated products. After washing, a disinfection is

performed introducing high temperature steam. All

these procedures are performed according to suitable

wash programs and following the instructions indicated

in the “Machine wash programs” paragraph.

Electricity is used to power the appliance and can also

be used to generate steam when the machine has a

built-in steam generator.

Containers are emptied automatically when the door is

closed. The material in the containers is dumped into

the wash chamber and passes through the drain trap to

go to the sewer system.

Washing is done using water coming directly from

the hot and cold water mains, with an anti-backflow

system according to EN 1717 Standards. Be advised

that wash programs are not influenced by variations in

water mains pressure as the machine has its own water

storage tank and a wash pump that takes the needed

water from this tank.

Disinfection is done introducing steam directly into the

wash basin. This steam can be generated either by a

special boiler called “steam generator" (if the machine

is equipped with this system), or can be taken directly

from a local steam pipeline network (if the building

has a steam pipeline network). In order for containers

introduced into the wash basin to be disinfected, the

temperature in the chamber must be kept above a

preset value (minimum 85°C/185°F) for a time period

of at least one minute.

The items to wash and disinfect are inserted on special

supports.

Every wash program of the device is totally automatic.

Once the wash cycle is started, the operator is free to

perform other tasks until the cycle is finished.

The validation process must be performed by the final

user, using the dirt, stated in the current regulations.

6.1 Configurations

6.1.1 Disinfecting systems

The machine can be equipped with two different

disinfecting systems:

Thermal disinfection with steam generator

During each wash cycle, a small boiler heat water to

generate steam using a heating coil. The device software

takes care of setting the disinfection temperature and

its duration.

All 15883 machines, when not used for 24 hours,

automatically start a disinfection cycle, composed by

some wash phases, a disinfection phase and a final

rinse with sanitized water (hotter than 65°C/149°F).

The door should always be closed when not working for

long periods of time, or, even better, after every wash

cycle, both for automatic and manual door.

Thermal disinfection with steam pipeline network

connection

Steam is taken directly from the local steam pipeline

network. Flow is regulated by a solenoid valve that

allows or prevents steam entrance into the basin to

perform the disinfection.

6.1.2 Safety thermostat

The machine model with steam generator, (meaning

with self-generated steam) is equipped with a safety

thermostat that interrupts power to the steam

generator heating coils when the temperature of the

heating coils exceeds a certain limit. Exceeding this

limit could cause damage to the heating elements. To

restart the appliance you must eliminate the causes

(the display will show the error message: "E40:

Overheating").

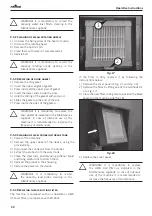

6.1.3 Automatic door

Door opening and closing is commanded by an electric

system actuated by a pedal-controlled switch and/

or by an infrared sensor. Touching the button for the

desired wash program causes the door to close and

after a few seconds, the wash cycle to start. A safety

device prevents the door from reopening before the

wash cycle is terminated. If during closing, the door

encounters any obstacle on its way, then it will partially

reopen to prevent damage to the person or object

on its way. If movement is blocked when the door is

opening then the door stops. The red push-button

instantaneously stops any machine function (including

door movement) in case of an emergency. To reset

machine operation just release the emergency push-

button, rotating it in the direction of the arrow.

Door opening at the end of the wash cycle is also be

automatic. This speeds up drying of the products being

washed and also informs the operator that the wash

cycle is terminated: the operator can see that the

appliance has terminated its work cycle and is ready to

start a new cycle.

b

WARNING! The red emergency push-

button blocks machine functions, it DOES

NOT interrupt electrical power. To interrupt

electrical power turn off the service switch or

the main switch.

Summary of Contents for DVS

Page 40: ...Operative Instructions 40 Notes ...

Page 41: ...Operative Instructions 41 Notes ...