24

CONVENTIONAL THERMOST

A

T WIRING

The RHPL-series air handler is shipped with “On Demand Dehumidification” (ODD)

turned OFF. On Demand Dehumidification is used in conjunction with a traditional

24VAC thermostat equipped with an on-board humidity sensor. Activate ODD by turn-

ing DIP switch 7 ON. ODD operation is controlled by the indoor humidity sensed at the

thermostat. Operation is:

Normal Humidity (humidity BELOW the thermostat set point):

High Humidity (humidity ABOVE the thermostat set point):

The RHPL air handler is programmed to provide maximum efficiency and optimum

humidity removal. When high humidity is detected, the air handler reduces cooling air-

flow defined in Table 9.

IMPORTANT: The DIP switches are active only when using conventional a 24VAC ther-

mostat. If using the Comfort Control

2

System™, refer to Section 5.17 for adjusting airflows.

(Refer to Section 5.9.)

N

NO

OT

TE

E:: ODD airflow adjustments are active for cooling operation only. They are

ignored when the heat pump is in heating mode or when electric heat is activated.

5.19 COOLING DELAY PROFILES

Cooling delay profiles are not available when the RHPL air handler is controlled using a

conventional 24VAC thermostat. These profiles are available only when the air handler

is wired for the Comfort Control

2

System™. Refer to Section 5.10 for Comfort Control

2

Cooling Delay Profiles wiring.

5.20 AIR HANDLER DIAGNOSTIC CODES

Descriptions of the air handler Comfort Control

2

diagnostic codes are provided below.

These codes can be displayed at the thermostat or via a diagnostic tool.

IMPORTANT: Air handler diagnostic codes are available at the thermostat when the

system is wired for Comfort Control

2

.

TABLE 10

SELECTION C EXPLANATION: ON DEMAND DEHUMIDIFICATION

SWITCH 7

POSITION

ODD

INPUT

COOLING AIRFLOW - CFM

RHPL-HM2421

Y1

Y2

Y2

Y2

Y2

Y1

Y1

Y1

RHPL-HM3621

RHPL-HM4824

RHPL-HM6024

NONE

500

625

725

950

950

1300

1100

1350

24VAC

625

775

900

1200

1200

1625

1375

1675

ON

TABLE 9

ODD AIRFLOW REDUCTION

11

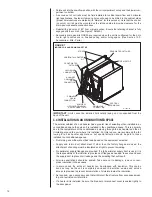

Figure X – On Demand Dehumidification DIP Switch

The (-)HPL-series air handler is shipped with “On Demand Dehumidification” (ODD) turned

OFF. On Demand Dehumidification is used in conjunction with a traditional 24VAC thermostat

equipped with an on-board humidity sensor. Activate ODD by turning DIP switch 7 ON. When

ODD is turned ON, the thermostat sends a 24VAC signal to the ODD input of the air handler.

Operation is:

Normal Humidity (humidity BELOW the thermostat set point):

Normal Humidity

Result

A 24VAC signal is applied to

the ODD terminal

Full rated airflow is delivered

by the blower

High Humidity (humidity ABOVE the thermostat set point):

High Humidity

Result

No signal applied to the ODD

terminal

Airflow is reduced by a preset

amount to increase latent

capacity

The (-)HPL air handler is programmed to provide maximum efficiency and optimum humidity

removal. When high humidity is detected, the air handler reduces cooling airflow defined in

Table X.X.

Air Handler

Cooling Airflow

Reduction

2-ton 85%

3-ton

4-ton

5-ton

80%

Table X.X – ODD Airflow Reduction

IMPORTANT:

The DIP switches are active only when using conventional a 24VAC

thermostat. If using serial communications, refer to section 5 for adjusting airflows.

11

Figure X – On Demand Dehumidification DIP Switch

The (-)HPL-series air handler is shipped with “On Demand Dehumidification” (ODD) turned

OFF. On Demand Dehumidification is used in conjunction with a traditional 24VAC thermostat

equipped with an on-board humidity sensor. Activate ODD by turning DIP switch 7 ON. When

ODD is turned ON, the thermostat sends a 24VAC signal to the ODD input of the air handler.

Operation is:

Normal Humidity (humidity BELOW the thermostat set point):

Normal Humidity

Result

A 24VAC signal is applied to

the ODD terminal

Full rated airflow is delivered

by the blower

High Humidity (humidity ABOVE the thermostat set point):

High Humidity

Result

No signal applied to the ODD

terminal

Airflow is reduced by a preset

amount to increase latent

capacity

The (-)HPL air handler is programmed to provide maximum efficiency and optimum humidity

removal. When high humidity is detected, the air handler reduces cooling airflow defined in

Table X.X.

Air Handler

Cooling Airflow

Reduction

2-ton 85%

3-ton

4-ton

5-ton

80%

Table X.X – ODD Airflow Reduction

IMPORTANT:

The DIP switches are active only when using conventional a 24VAC

thermostat. If using serial communications, refer to section 5 for adjusting airflows.

11

Figure X – On Demand Dehumidification DIP Switch

The (-)HPL-series air handler is shipped with “On Demand Dehumidification” (ODD) turned

OFF. On Demand Dehumidification is used in conjunction with a traditional 24VAC thermostat

equipped with an on-board humidity sensor. Activate ODD by turning DIP switch 7 ON. When

ODD is turned ON, the thermostat sends a 24VAC signal to the ODD input of the air handler.

Operation is:

Normal Humidity (humidity BELOW the thermostat set point):

Normal Humidity

Result

A 24VAC signal is applied to

the ODD terminal

Full rated airflow is delivered

by the blower

High Humidity (humidity ABOVE the thermostat set point):

High Humidity

Result

No signal applied to the ODD

terminal

Airflow is reduced by a preset

amount to increase latent

capacity

The (-)HPL air handler is programmed to provide maximum efficiency and optimum humidity

removal. When high humidity is detected, the air handler reduces cooling airflow defined in

Table X.X.

Air Handler

Cooling Airflow

Reduction

2-ton 85%

3-ton

4-ton

5-ton

80%

Table X.X – ODD Airflow Reduction

IMPORTANT:

The DIP switches are active only when using conventional a 24VAC

thermostat. If using serial communications, refer to section 5 for adjusting airflows.

Summary of Contents for RHPL-HM2421JC

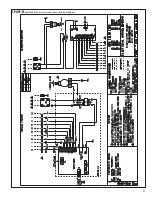

Page 37: ...37 FIGURE 29 AIR HANDLER EQUIPPED WITH Serial Communication WIRING DIAGRAM...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40 CM 0411...