16

• Do not leave excess field control wiring inside unit, pull excess control wire to outside

of unit and provide strain relief for field wiring on inside of cabinet at point wiring pene-

trates cabinet.

• Make sure, after installation, separation of control wiring and power wiring has been

maintained.

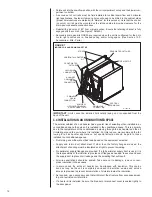

5.2

Comfort Control

2

System™

CONTROL BOARD

The RHPL series air handler control, Figure 8, has the following features:

• Memory Card – The memory card stores all information needed for unit operation.

Once the system is wired for serial communications, this information is shared with the

thermostat and outdoor unit. This shared data is available if one of the components in

the system needs to be replaced.

• An automotive-style ATC blade fuse for transformer protection (3 amp).

• An on-board LED to indicate blower CFM.

• An RJ-11 port for use with a diagnostic tool.

• Inputs for field installed supply and return air temperature sensors (available in kit

RXHT-A01)

• DIP switches for airflow adjustments

IMPORTANT: The DIP switches are NOT used when the air handler is wired for serial

communications. Airflow adjustments are performed via the thermostat or a diagnostic

tool.

Installation Verification

• Term and bias dip switches should be on.

• 24V AC power on R&C must be present at the control for the air handler to operate,

reference Figure 9.

• Line voltage must be present at the control for indoor blower operation.

• The RX Data LED will flash green in normal operation. A flashing green light indicates

24VAC is present and the data wires 1 and 2 are wired properly.

IMPORTANT: Diagnostic port is for the diagnostic tool only. Do not attempt to connect

components using a telephone cord. Damage will occur.

IMPORTANT: Diagnostic port is not a phone jack. Connecting to a telephone or tele-

phone system will result in damage.

5.3 USING THE ON-BOARD LED TO DETERMINE BLOWER CFM

The CFM LED indicates blower output by flashing one (1) flash for every 100 CFM of

airflow. The LED will pause 1/10 second between each flash.

5.4 AIRFLOW ADJUSTMENTS WITH THE

Comfort Control

2

System™

The RHPL air handler Comfort Control

2

System™ may operate using the Comfort

Control

2

or via traditional thermostat wiring. When the air handler is wired for the

Comfort Control

2

using Data wire 1 and Data wire 2, the DIP switches on the Comfort

Control

2

control have NO affect on the airflow.

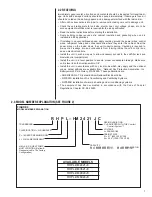

FIGURE 9

TYPICAL The Comfort Control

2

System™ WIRING DIAGRAM

Indoor Unit

1

2

C

R

WIRING INFORMATION

Line Voltage

–Field Installed - - - - - -

–Factory Standard

1

2

R

C

1

2

R

C

Communicating Thermostat

Outdoor Unit

Comfort Control

2

System™

CONTROL WIRING

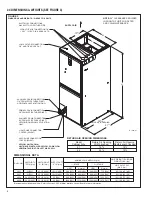

Summary of Contents for RHPL-HM2421JC

Page 37: ...37 FIGURE 29 AIR HANDLER EQUIPPED WITH Serial Communication WIRING DIAGRAM...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40 CM 0411...