9. Maintenance

(EX-PS only)

The bar rail should always be a square. Check for

wear of the bar rail. Apply a ruler to the bar and the

outside of a cutter. If a gap is observed between

them, the rail is normal. Otherwise, the bar rail is

worn. Such a bar needs to be corrected or

replaced.(MA4)

(1) Ruler

(2) Gap

(3) No gap

(4) Chain tilts

■

SPROCKET

Check for extensive wear, and replace it when the

teeth are worn over 0.3mm. (MA5)

(1) Sprocket

■

SAW CHAIN

It is very important for smooth and safe

operation to keep the cutters always sharp.

Your cutters need to be sharpened when:

• Sawdust becomes powder-like.

• You need extra force to saw in.

• The cut way does not go straight.

• Vibration increases.

• Fuel consumption increases.

Cutter setting standards:

Be sure to wear safety gloves.

Before filing:

• Make sure the saw chain is held securely.

• Make sure the engine is stopped.

• Use a round file of proper size for your chain.

Chain type :

90SG

File size

:

5/32 in (4.0mm)

Place your file on the cutter and push straight

forward. Keep the file position as illustrated. (MA6)

WARNING

WARNING

EX-PS

MA4

EX-PS

MA5

EX-PS

MA6

41

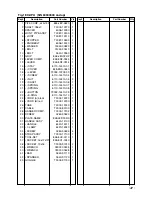

Summary of Contents for EXtreme EX-HE

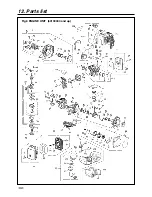

Page 46: ...12 Parts list 46 Fig 1 EXZ PU S N 60300000 and up...

Page 48: ...12 Parts list 48 Fig 2 EX2 BC S N 50200000 and up...

Page 50: ...Fig 3 ENGINE UNIT 60100000 and up 50 12 Parts list...

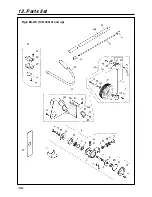

Page 52: ...12 Parts list 52 Fig 4 EX LRT S N 000531 and up...

Page 54: ...12 Parts list 54 Fig 5 EX PS S N 000000 and up...

Page 56: ...12 Parts list 56 Fig 6 EX HE S N 000101 and up...